Iwebhusayithi: www.welding-honest.com Whatsapp:+86 13252436578

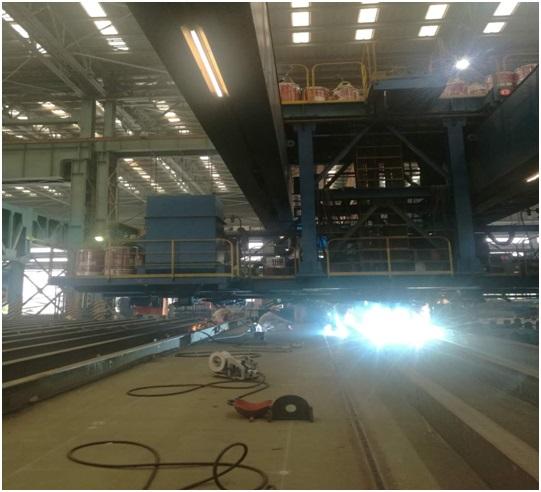

Emsebenzini wokushisela wokwakha umkhumbi, amabhuloho, izakhiwo zensimbi nezinye izimboni, kuvame ukushiselwa ama-angle kwesokudla amade ashiselwe, futhi ukushisela okuzenzakalelayo kusetshenziswa kakhulu, ngezinqola zokushisela, izingalo zokushisela ezizenzakalelayo nezindlela zokushisela zama-multi-electrode.Ngokushisela i-T-row multi-electrode, inkampani yethu yethule i-GFL-70C iron powder flux cored wire ene-GCL-11G metal powder type welding wire, eyamukelwa amakhasimende amaningi ngokwengeziwe.Le ndlela yokuhlanganisa i-welding inejubane eliphezulu lokushisela, i-primer enhle kakhulu ye-zinc powder-resistant, kanye nokwakheka okuhle kobuhlalu be-weld.Ukusebenza kahle kwe-deposition yocingo lwangaphambili lwe-GCL-11G kuphakeme njengo-97%, ikakhulukazi ngenxa yenani lensimbi yokugcwalisa, futhi i-wire yangemuva i-GFL-70C iqinisekisa ukwakheka kobuhlalu be-weld, futhi isivinini sokushisela singafinyelela ku-1000-1400mm. /min.Ngokuyinhloko ifaneleka ukushisela okuyisicaba kanye ne-flat fillet welding yezakhiwo ezihlukahlukene njengemikhumbi, amabhuloho, imishini, izimoto kanye nezakhiwo zensimbi.

I-Multi-electrode T-row enesivinini esikhulu futhi esebenzayo

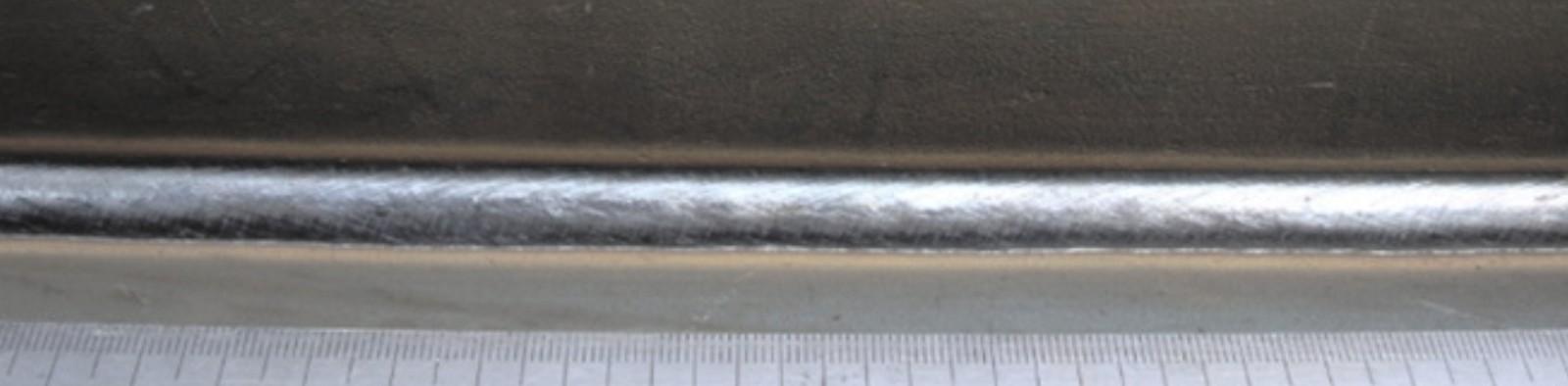

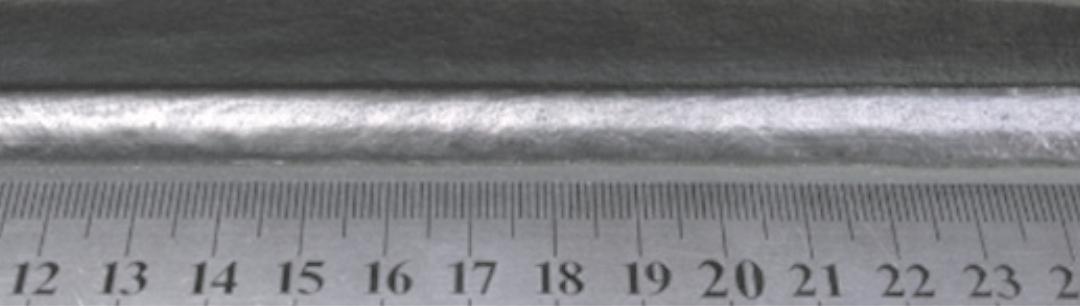

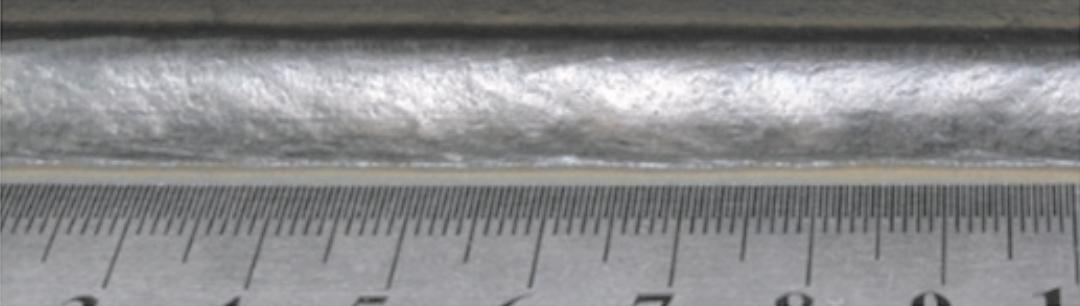

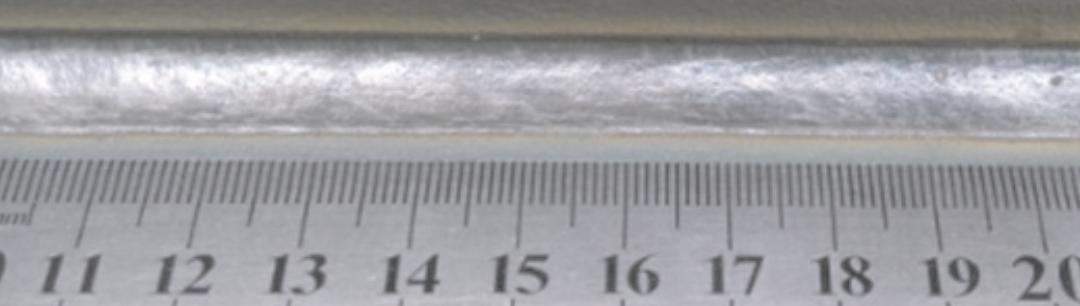

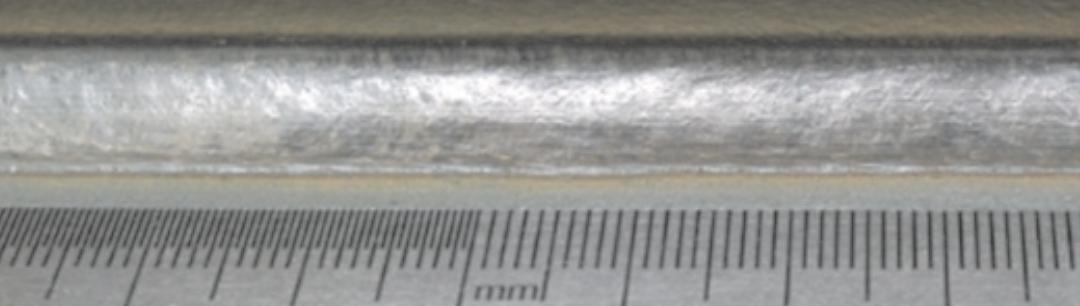

Ukubukeka kokususwa kwe-weld slag

Ngaphambi kokutshala

Ngemuva kokuhlinzwa

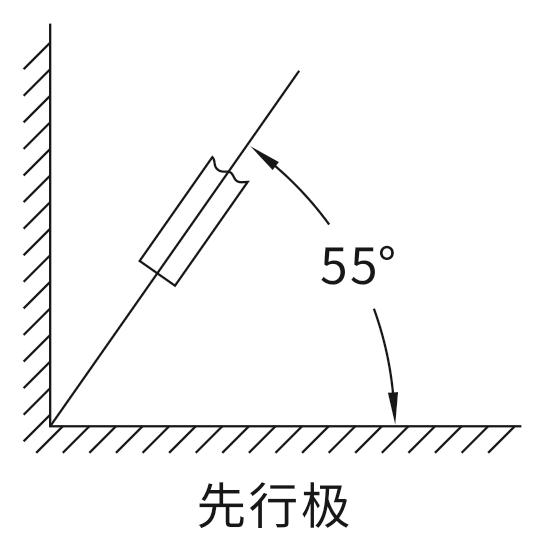

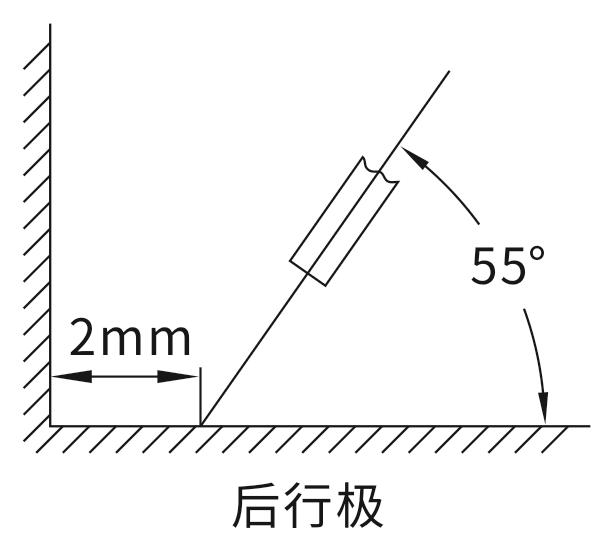

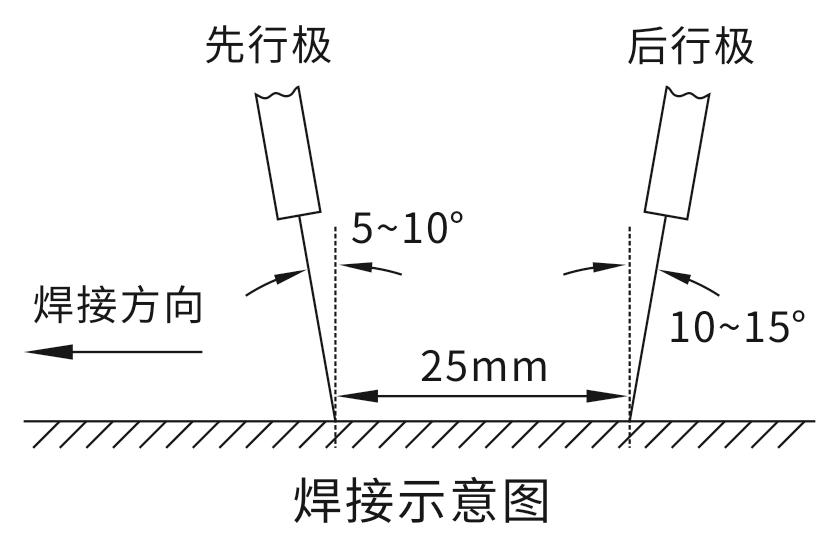

Isici esikhulu kunazo zonke sale ndlela yokushisela ukusebenza kwayo okuphezulu, i-multi-electrode welding ngesikhathi esifanayo, futhi asikho isidingo sokukhathazeka mayelana nokuphazanyiswa kwe-polarity kanye ne-magnetic field.Iqembu ngalinye le-fillet welds linamasethi amabili amathoshi okushisela, futhi iqembu ngalinye linezintambo zangaphambili nangemuva.Intambo yangaphambili inokumelana okungcono kwe-porosity futhi isebenza njengesamba esikhulu sensimbi yokugcwalisa.Intambo yangemuva idinga kuphela ukuqinisekisa ukuthi ubuhlalu obushiselayo bubunjwa buyisicaba, bufane futhi buhlanzeke.Izici ezikhona zohlobo lwe-iron powder flux wire cored, njengocingo lwangemuva lwale nhlanganisela, lungavele luhlangabezane nezidingo zokwakheka nokubukeka kwayo okuhambisanayo.I-angle yethoshi yokushisela kanye nokulungiswa kwebanga lale ndlela yokushisela kukhonjiswe esithombeni esingezansi:

I-Hybrid high speed fillet welding:

Qaphela: Lungisa ibanga phakathi kwezintambo zangaphambili nezingemuva ngokuya ngokushisa kwangempela kwechibi elincibilikisiwe ngesikhathi sokushisela.

Le ndlela yokushisela ingathola ukulindela okufunayo kwe-welding ngokulungisa imingcele ye-welding ehlukene.Ngokulungisa i-welding current, i-voltage, isivinini sokushisela, ibanga lethoshi le-welding, njll., amasayizi ahlukene we-welding angle angatholakala.

Isibonelo sokushisela i-fillet high speed 1

I-GCL-11G (i-electrode ethuthukisiwe)/GFL-70C (i-electrode yangemuva) 1.4mm:

| Okwamanje kanye voltage | isivinini sokushisela mm/min | Ubude bomlenze we-solder |

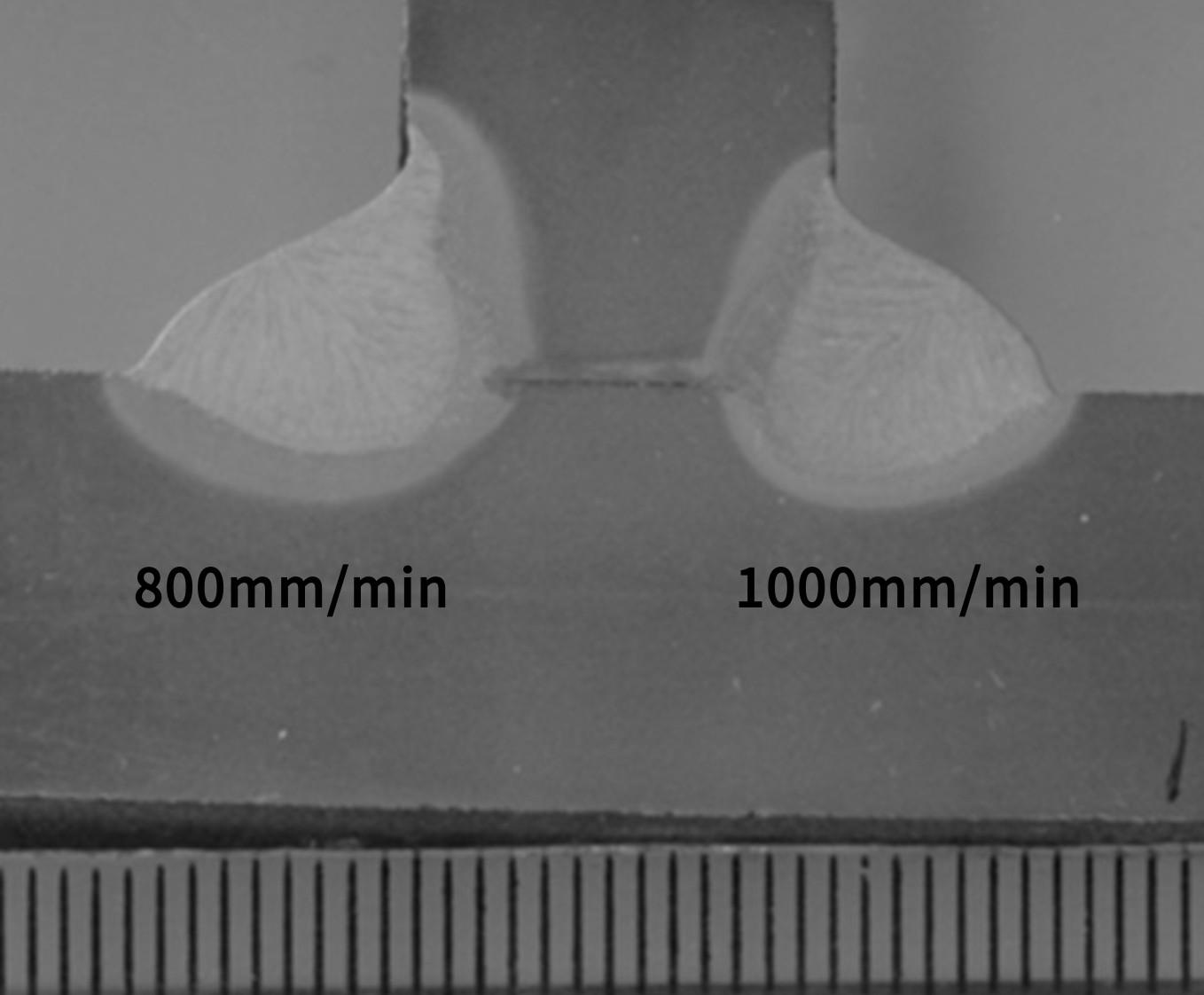

| I-Pioneer 360A/32V Isigaba sokulandelela 360A/38V Isikhala se-Electrode 25MM | 800 | 9-10 |

| 1000 | 7-8 |

| ubude bonyawo | 9.0 | ubude bonyawo | 7.0 | |

| I-Convexity | 0.4 | I-Convexity | 0.8 | |

| Ukungena | 2.0 | Ukungena | 2.2 |

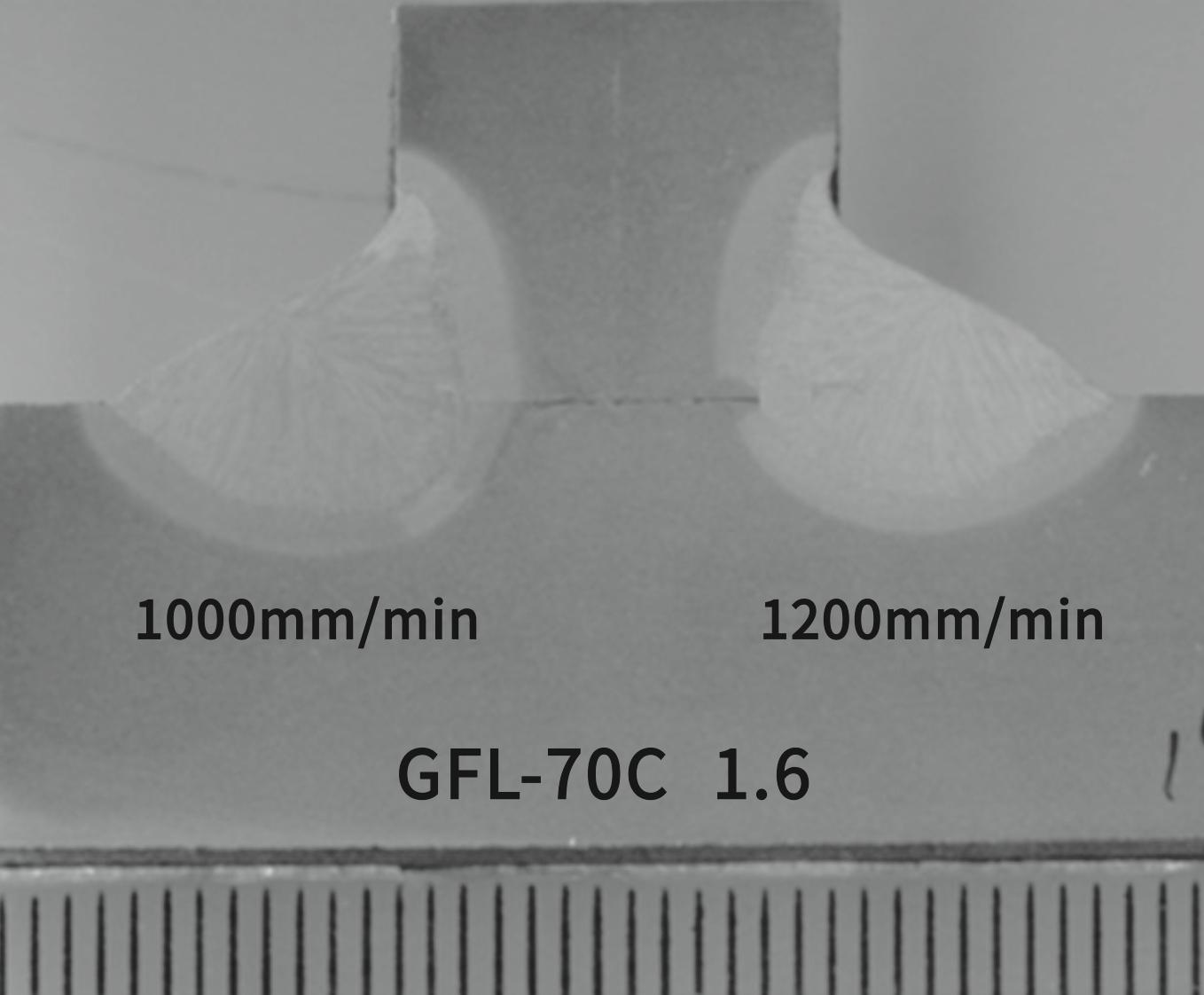

Isibonelo sokushisela i-fillet esinesivinini esiphezulu kakhulu 2

I-GCL-11G (i-electrode ethuthukisiwe)/GFL-70C (i-electrode yangemuva) 1.6mm:

| Okwamanje kanye voltage | isivinini sokushisela mm/min | Ubude bomlenze we-solder |

| I-Pioneer 360A/32V Isigaba sokulandelela 360A/38V Isikhala se-Electrode 25MM | 1000 | 8-9 |

| 1200 | 7-8 |

Ukutholwa kokungena

| ubude bonyawo | 8.0 |

| ubude bonyawo | 7.0 |

| I-Convexity | 0 | I-Convexity | 0.3 | |

| Ukungena | 2.4 | Ukungena | 2.7 |

Izincomo zesimo sokushisela i-GCL-11G+GFL-70C

| Isigaba sokushisela | Ukucaciswa mm | imininingwane yokushisela | isivinini sokushisela mm/min | Usayizi womlenze we-solder mm | Phawula | |

| Usilika wangaphambili | Usilika wangemuva | |||||

| inhlanganisela | 1.4 | 350-400A 32-36V | 320-380A 36-38V | 700- 1000 | 5-8 | Intambo yangaphambili yi-GCL-11G, ikakhulukazi esetshenziselwa ukugcwalisa, i-high current, i-voltage ephansi;ucingo olungemuva luyi-GFL-70C, i-voltage ephezulu, yamanje ephansi |

| 1.6 | 360-420A 36-38V | 320-400A 36-38V | 1000- 14000 | 5-8 | ||

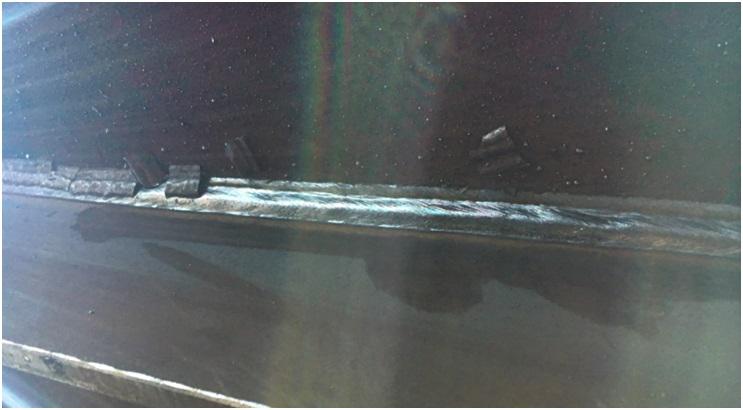

Okunye: I-9-12mm welding angle ingafinyelelwa ngokulungisa i-angle yethoshi ethize kanye nesivinini sokushisela.Weld bead njengoba kukhonjisiwe ngezansi:

12mm i-angle yokushisela enkulu

Ngale ndlela yokushisela, sicela futhi ulandele izincomo zokushisela ezilandelayo kanye nezinyathelo zokuphepha

1. Hlanza imfucumfucu, ukugqwala, amabala kawoyela, nezinsalela ze-oxidation, ngaphandle kwalokho kungase kubangele izimbotshana noma amaphutha njengokubunjwa kabi.

2. Okuqukethwe komhwamuko wamanzi okweqile kuzothinta ikhwalithi yokushisela futhi kubangele izimbotshana.Uma umswakama uphezulu, ukukhishwa kwe-humidification efanele kufanele kwenziwe ngaphambi kokushisela, futhi ukushisela okuhlangothini olulodwa ebusuku kufanele kugwenywe.

3. Ubukhulu befilimu kapende ngokuvamile bulawulwa ku-15-35um.Uma ubukhulu befilimu kapende bukhulu kakhulu, buzobangela kalula ama-pores, futhi budinga ukupholishwa uma kunesidingo.

4. Izinga lokugeleza kwegesi lilawulwa ku-20-25l / min, ukuphakama okomile kulawulwa cishe ku-20 ~ 25mm, futhi isivinini somoya sidlula i-2m / s, futhi indawo yokuhlala edingekayo iyadingeka.

5. Uma i-welding ihlanganisiwe:

(1) Iphaneli yamandla we-welding ye-GCL-11G yangaphambili ikhetha igiya eliqinile, futhi iphaneli yamandla yokushisela ye-GFL-70C yangemuva ikhetha igiya eliyinhloko;

(2) Lapho i-welding fillet welds, iqembu ngalinye lama-quadrupole lenziwa ngendlela yokubhekana nomunye nomunye ngezintambo zangaphambili nangemuva.

Lokhu okungenhla okokubhekisela kuphela, ngicela ukhululeke ukungikhanyisela uma kukhona okungalungile.

More information send E-mail to export@welding-honest.com

Isikhathi sokuthumela: Dec-20-2022