I. Uhlolojikelele

Ngokuthuthuka okusheshayo kwamakhemikhali omhlaba kanye nempahla yamandla, amathangi okugcina insimbi engagqwali neziqukathi zisetshenziswa kabanzi ekuthuthweni nasekugcinweni kwamakhemikhali, ukudla nesiphuzo, amandla nezinye izinto.Ngenxa yokuqina kwayo okuhle kakhulu kwezinga lokushisa eliphansi kanye nokumelana nokugqwala okuhle, insimbi engagqwali ye-austenitic isetshenziswa kabanzi ekwakhiweni kwamathangi okugcina ama-cryogenic, imishini kanye nezakhiwo ezinkulu ze-cryogenic.

I-Cryogenic storage tank

2. Ukwethulwa kafushane kwe- -196 ℃ izinga lokushisa eliphansi elinomthelela ezintweni ezisetshenziswayo zokushisela insimbi engagqwali

| Isigaba | Igama | Imodeli | Okujwayelekile | Phawula | |

| I-GB/YB | AWS | ||||

| I-Electrode | I-GES-308LT | A002 | I-E308L-16 | I-E308L-16 | -196℃≥31J |

| I-Flux wire | I-GFS-308LT | - | I-TS 308L-F C11 | I-E308LT1-1 | -196℃≥34J |

| Ucingo oluqinile | I-GTS-308LT (TIG) | - | I-H022Cr21Ni10 | I-ER308L | -196℃≥34J |

| I-GMS-308LT (MIG) | - | I-H022Cr21Ni10 | I-ER308L | -196℃≥34J | |

| SAW | GWS-308/ I-GXS-300 | - | I-S F308L FB-S308L | I-ER308L | -196℃≥34J |

3.I-electrode yethu i-GES-308LT (E308L-16)

Ukuze kuhlangatshezwane nesidingo semakethe, inkampani yethu ithuthukise izinga lokushisa elisezingeni eliphansi kakhulu, ukuqina okuphezulu kwama-electrode ensimbi engagqwali ye-austenitic, ukwakheka kwamakhemikhali ensimbi ediphozithisiwe (njengoba kuboniswe kuThebula 1) kanye nezakhiwo ezizinzile zemishini (njengoba kuboniswe kuThebula. 2), futhi inenqubo yokushisela yezindawo zonke ezinhle kakhulu Ukusebenza, kanye nokuqina komthelela wokushisa okuphansi okuhle kakhulu, umthelela yenani layo le-ferrite kunani lomthelela (Ithebula 3).

1.Ukwakheka kwamakhemikhali ensimbi efakiwe

| I-E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| NB (%) | 0.04 | 0.5-2.5 | 1.0 | 0.030 | 0.020 | 9.0-12.0 | 18.0-21.0 | 0.75 | 0.75 | - | - |

| Isampula1 | 0.022 | 1.57 | 0.62 | 0.015 | 0.006 | 10.25 | 19.23 | 0.020 | 0.027 | 0.046 | 6.5 |

| Isampula2 | 0.037 | 2.15 | 0.46 | 0.018 | 0.005 | 10.44 | 19.19 | 0.013 | 0.025 | 0.45 | 3.8 |

| Isampula3 | 0.032 | 1.37 | 0.49 | 0.017 | 0.007 | 11.79 | 18.66 | 0.021 | 0.027 | 0.048 | 0.6 |

Ithebula 1

2.Izakhiwo zemishini yensimbi efakiwe

| I-E308L-16 | Veza I-MPa | I-tensile I-MPa | Ukwelula % | -196℃faka u-J/℃ | I-GB/T4334-2020 E I-Intergranular corrosion | Rukuhlolwa kwe-adiographic | Phawula | |

| Inani elilodwa | Inani elimaphakathi | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Isampula1 | 451 | 576 | 42 | 32/32/33 | 32.3 | abafanelekile | I | - |

| Isampula2 | 436 | 563 | 44 | 39/41/39 | 39.7 | abafanelekile | I | - |

| Isampula3 | 412 | 529 | 44.5 | 52/53/55 | 53.3 | abafanelekile | I | - |

Ithebula 2

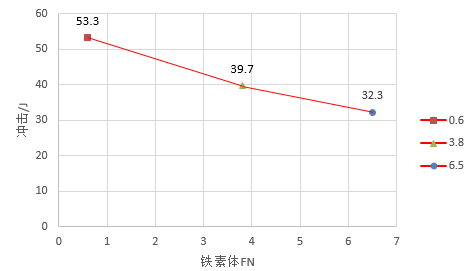

3.Umphumela yenani le-ferrite yensimbi efakiwe kumthelela

4.Ukubonisa inqubo yokushisela (φ3.2mm)

Ukushisela okuqondile ngaphambi nangemuva kokususwa kwe-slag (DC+)

Ukushisela amapayipi ngaphambi nangemva kokususwa kwe-slag (DC+)

4. Izinyathelo zokuqapha zokushisela okuqondile

1. I-welding yamanje ephansi kufanele isetshenziswe;

2. Gcina i-arc iphansi ngangokunokwenzeka;

3. Uma i-arc inyakaza ezinhlangothini zombili ze-groove, yima isikhashana, futhi ububanzi be-swing bulawulwa ngaphakathi kwezikhathi ezi-3 ububanzi be-electrode.

5.Pipeline picture of Welding okudlekayo isicelo

Ku--196 ℃ izinga lokushisa eliphansi elinomthelela wezinto ezisetshenziswayo zokushisela insimbi engagqwali, ngemva kweminyaka yocwaningo nokuthuthukiswa kwezinto ezisebenzisekayo zokushisela, sesivele sinezinto ezisetshenziswayo zokushisela ezihambisanayo zezinduku zokushisela, ama-cores aqinile, ama-flux cores nama-arcs angaphansi, futhi sesenze i-arc eqhubekayo ye-electrode yesandla. izinto zokushisela zokushisela zonke-izikhundla, futhi inezimpumelelo eziningi zohlelo lobunjiniyela, wamukelekile amakhasimende ukuthi abonane futhi akhethe!

Isikhathi sokuthumela: Dec-16-2022