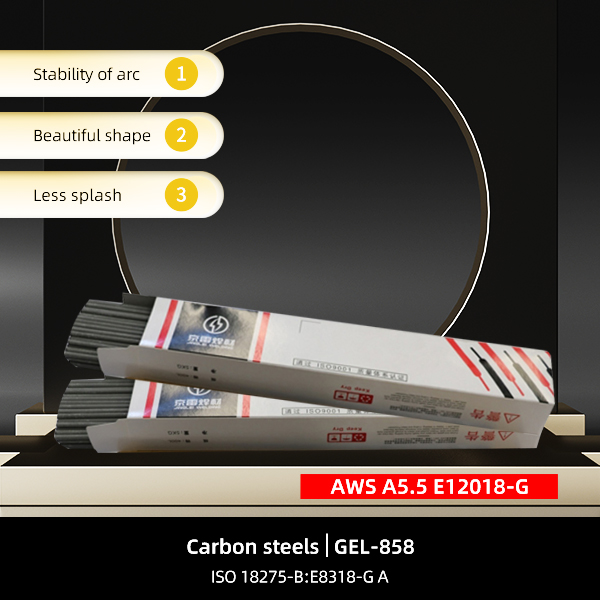

620Mpa Hand Electrode For High Amandla Steel

Isicelo&Standard

1. Ifanele insimbi ye-alloy yegolide ephansi, i-medium carbon steel welding, njengemishini yokwakha, imishini yechweba nezinye izikhathi.

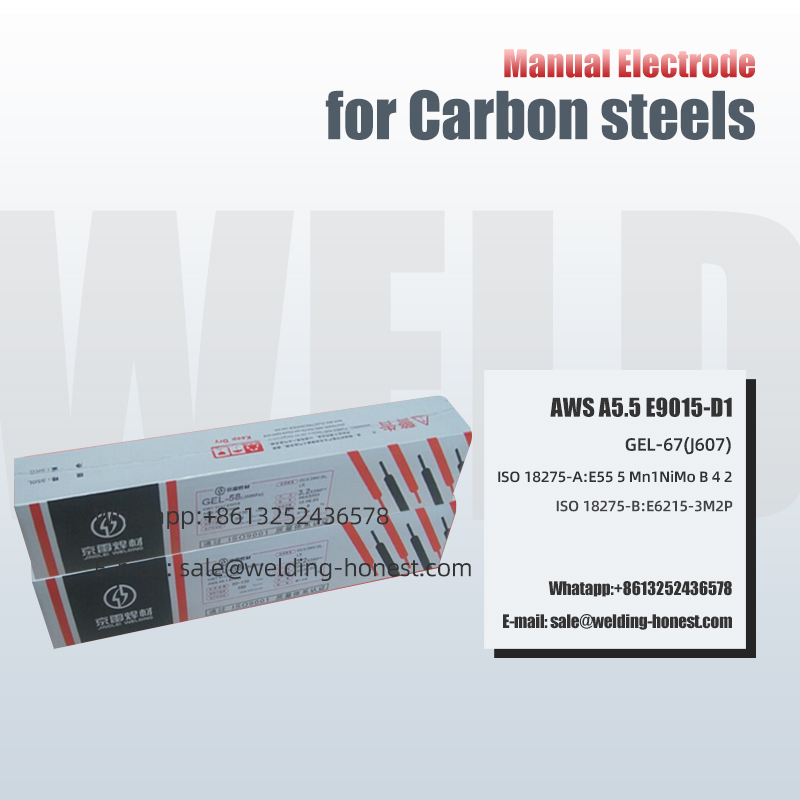

2. Izinga esihlangabezane nalo: GB/T32533 E5918-G P, AWS A5.5 E9018-G & A5.5M E6218-G, ISO18275-A:E 55 5 1.5NiMo B 3 2, ISO18275-B: E6218-G P

Ukushisa kwangaphambi kokushisa kanye nezinga lokushisa eliphakathi kwesiteshi: 150±15℃, ukwelashwa kokushisa ngokwezidingo ezijwayelekile zezinto zokushisela, 620±15℃*1 ihora lokwelashwa kokushisa kwangemva kokushisela.

I-E9016 iyisikhumba esiphansi se-hydrogen potassium sohlobo lwesidakamizwa se-electrode yensimbi enamandla amakhulu, i-AC ne-DC ukusetshenziswa okukabili, i-AC welding, ekusebenzeni kokuzinza, engaphansi kancane kune-DC welding, esetshenziselwa ukushisela insimbi ye-carbon medium namandla ahambisanayo aphansi. ingxubevange high amandla isakhiwo steel, ezifana 15MnVN steel. Ngaphambi kokushisela, i-electrode kufanele ibhakwe ku-350 ℃ ihora elingu-1, bese isetshenziselwa ukubhaka. Uma ukushisela kushubile, kufanele kushiswe kuqala ngaphezu kuka-150 ℃ futhi kupholiswe kancane ngemva kokushisela.

Izici

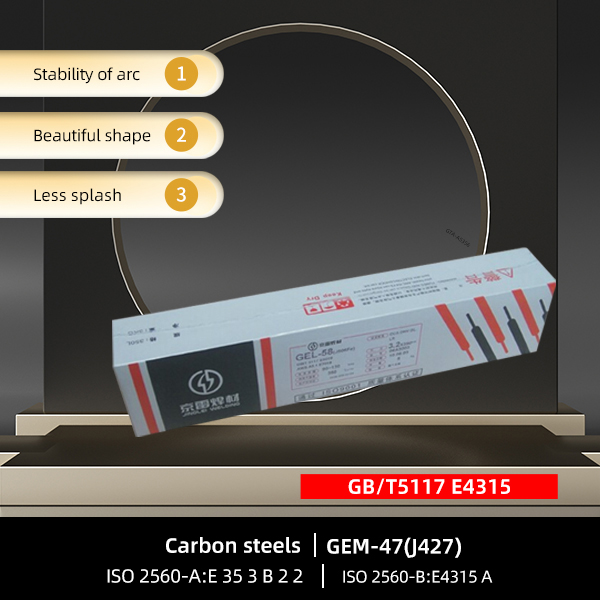

1. I-iron powder low hydrogen hand electrode, ukusebenza kahle okuphezulu, i-arc ezinzile, i-splash encane, ukubunjwa okuhle, ukuchithwa okulula, ukusebenza kwe-X-ray kuhle kakhulu.

2. Inokumelana nokuqhekeka okuhle kanye nezakhiwo ezizinzile zemishini.

Imodeli ye-electrode yensimbi enamandla amakhulu engu-J606: I-E9016-G izici zensimbi ezinamandla aphezulu: uhlobo oluphansi lwe-hydrogen potassium uhlobo oluphansi lwe-alloy high amandla ensimbi i-electrode, i-AC ne-DC ukusetshenziswa okukabili, ingaba i-welding endaweni egcwele, i-AC yokushisela, ukuqina kokusebenza kwenqubo kungaphansi kancane I-DC welding. Inhloso: Insimbi ye-carbon emaphakathi kanye nebanga lamandla elihambisanayo nensimbi eqinile esezingeni eliphansi, njenge-15MnVN.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMITHETHO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS IMITHETHO | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.03 | 0.03 | ≥0.11 |

| ISIBONELO VALUE | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | ||||||

| GB/T IMITHETHO | 490 | 590 | 620*1 | ||||||

| AWS IMITHETHO | 530 | 620 | 620*1 | ||||||

| ISIBONELO VALUE | 600 | 685 | 620*1 | ||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| Ugesi | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding

Amacala Ajwayelekile

Isitifiketi

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMITHETHO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS IMITHETHO | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.03 | 0.03 | ≥0.11 |

| ISIBONELO VALUE | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | ||||||

| GB/T IMITHETHO | 490 | 590 | 620*1 | ||||||

| AWS IMITHETHO | 530 | 620 | 620*1 | ||||||

| ISIBONELO VALUE | 600 | 685 | 620*1 | ||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| Ugesi | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding