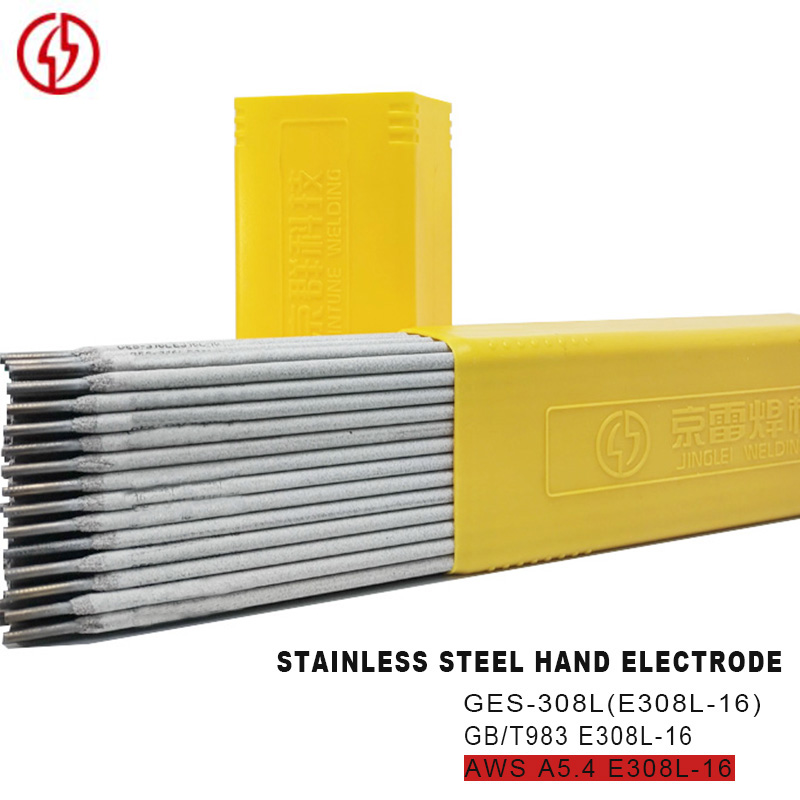

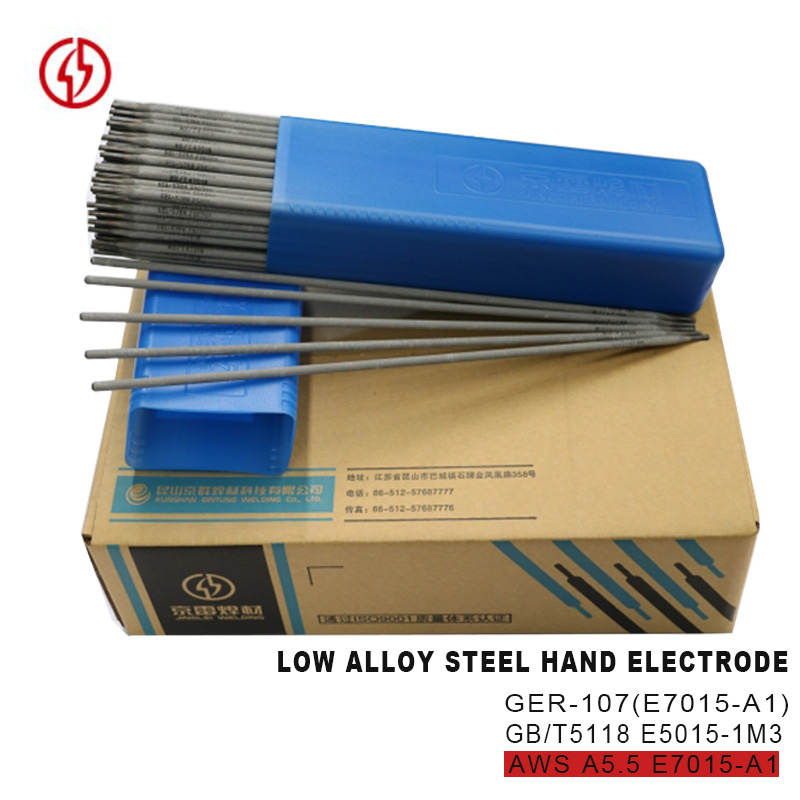

Eklanywe kahle i-Atlantic Stainless Steel Electrode E308L-16 2.5/3.2/4.0mm Umkhiqizi we-OEM Rutile Coated Pressure Welding Rod

Ngokuhambisana nomgomo “wekhwalithi, umhlinzeki, ukusebenza nokukhula”, manje sesithole ukwethenjwa nezindumiso kubathengi basekhaya nabaphesheya kwezwekazi le-Atlantic Stainless Steel Electrode E308L-16 Eklanywe Kahle 2.5/3.2/4.0mm Umkhiqizi we-OEM Rutile Coated Pressure Welding Rod, Abasebenzi bethu abanokuhlangenwe nakho okuyinkimbinkimbi bangase basekele ngenhliziyo yakho yonke ekusekeleni kwakho. Siyakwamukela ngempela ukuthi uvakashele iwebhusayithi yethu kanye nenkampani futhi usithumelele uphenyo lwakho.

Ngokuhambisana nomgomo "wekhwalithi, umhlinzeki, ukusebenza nokukhula", manje sesithole ukwethenjwa nezindumiso kubathengi basekhaya nabaphesheya kwezilwandleI-China Welding Rod kanye ne-E308L-16, Silwela ukwenza kahle, ukuthuthuka okuqhubekayo kanye nokuqamba izinto ezintsha, sizibophezele ukusenza “ukwethenjwa kwekhasimende” kanye “nenketho yokuqala yomkhiqizo wezisekeli zemishini yobunjiniyela”. Sikhethe, wabelane ngesimo sokuwina-win!

Isicelo&Standard&Note:

1. Ifanele i-petrochemical, isitsha sokucindezela, imishini yokudla, imishini yezokwelapha, umanyolo nezinye izimboni, i-welding 18% CR-8% Ni insimbi engagqwali (SUS304L, njll.)

2. Izinga esihlangabezane nalo: GB/T983 E308L-16, AWS A5.4 E308L-16 & A5.4M E308L-16, ISO3581-A:E(19 9 L) R 1 2, ISO3581-B:ES308L-16 , JIS Z3221 ES308L-16

I-E308L-16 yenzelwe ukushisela i-304L, le electrode ifaka u-0.04% wekhabhoni ensimbi yokushisela, Le electrode yokushisela isetshenziselwa kakhulu ukushisela imishini yezitshalo zamakhemikhali futhi ingasetshenziswa ngempumelelo ezinhlotsheni zokushisela ezingama-321 namamaki angama-347 ensimbi, Lokhu induku yokushisela inciphisa ukwakheka kwe-chromium carbides kunsimbi yokushisela.

Izici

1. I-Titanium calcium i-electrode yensimbi engagqwali, ukwakheka okuyinhloko kuphansi kwe-carbon-18Cr-9%Ni-4%;

2. I-arc ezinzile, ukwakheka okuhle, ama-ripples amahle, ama-splashes ambalwa, i-de-slagging elula, ukumelana nomlilo okuhle kwesikhumba sezidakamizwa, ukumelana okuhle kwesisu.

3. Izakhiwo zemishini ezinzile, izinga lokuphasa nge-X-ray liphezulu.

Stick Electrodes, AWS Classification E308-16, Material Stainless Steel, Process Stick Welding (SMAW), For Material Type Stainless Steel to Stainless Steel, Welding Current Designation AC, DCEP, For Welding Position Flat, Horizontal, Overhead, Vertical-Up

I-E308-16 insimbi engagqwali welding electrode iwuhlobo lwe-Titanium calcium yohlobo lwe-electrode yensimbi engagqwali i-Cr18Ni9, Insimbi ediphozithiwe inezinto ezinhle zokuwumshini kanye nokumelana nokugqwala kwe-intergranular,Inokusebenza okuhle kwe-welding kanye nokumelana ne-porosity, Ukumelana nokushisa nokumelana nokuqhekeka. I-AC/DC+ yomibili ingasetshenziswa.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMITHETHO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-12.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| AWS IMITHETHO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| ISIBONELO VALUE | 0.029 | 0.89 | 0.75 | 19.7 | 9.5 | 0.01 | 0.024 | 0.004 | 0.1 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | LONGATION(%) | |||||||||

| GB/T IMITHETHO | - | 510 | - | - | 30 | |||||||||

| AWS IMITHETHO | - | 520 | - | - | 30 | |||||||||

| ISIBONELO VALUE | - | 595 | - | - | 42 | |||||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| Ugesi (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IMINININGWANE YOKUPAKA:

| UKWEHLUKANA | LENGTH | PCS/1KG | Isisindo/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding

Amacala Ajwayelekile

Isitifiketi

Ngokuhambisana nomgomo “wekhwalithi, umhlinzeki, ukusebenza nokukhula”, manje sesithole ukwethenjwa nezindumiso kubathengi basekhaya nabaphesheya kwezwekazi le-Atlantic Stainless Steel Electrode E308L-16 Eklanywe Kahle 2.5/3.2/4.0mm Umkhiqizi we-OEM Rutile Coated Pressure Welding Rod, Abasebenzi bethu abanokuhlangenwe nakho okuyinkimbinkimbi bangase basekele ngenhliziyo yakho yonke ekusekeleni kwakho. Siyakwamukela ngempela ukuthi uvakashele iwebhusayithi yethu kanye nenkampani futhi usithumelele uphenyo lwakho.

Iklanywe kahleI-China Welding Rod kanye ne-E308L-16, Silwela ukwenza kahle, ukuthuthuka okuqhubekayo kanye nokuqamba izinto ezintsha, sizibophezele ukusenza “ukwethenjwa kwekhasimende” kanye “nenketho yokuqala yomkhiqizo wezisekeli zemishini yobunjiniyela”. Sikhethe, wabelane ngesimo sokuwina-win!

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMITHETHO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-12.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| AWS IMITHETHO | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| ISIBONELO VALUE | 0.029 | 0.89 | 0.75 | 19.7 | 9.5 | 0.01 | 0.024 | 0.004 | 0.1 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | LONGATION(%) | |||||||||

| GB/T IMITHETHO | - | 510 | - | - | 30 | |||||||||

| AWS IMITHETHO | - | 520 | - | - | 30 | |||||||||

| ISIBONELO VALUE | - | 595 | - | - | 42 | |||||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| Ugesi (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IMINININGWANE YOKUPAKA:

| UKWEHLUKANA | LENGTH | PCS/1KG | Isisindo/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding