Umbhoshongo usetshenziselwa ukucwiliswa emanzini, ukuhlanzwa, ukumuncwa, ukucwiliswa emanzini kanye nezinye izinto zamakhemikhali, amadivaysi amaningi ombhoshongo adinga ukuxhumana ne-asidi, i-alkali, usawoti, izinyibilikisi ze-organic kanye nezinye imidiya ezonakalisayo, ngakho-ke kuyadingeka ukudlula indawo enkulu yongqimba olumelana nokugqwala. ku-cylinder kanye nezingxenye zokuvala. Njengendlela ephumelelayo yokubeka phezulu, i-strip surfing isetshenziswa kabanzi ekushiseleleni umbhoshongo wemishini yamakhemikhali.

Ubuchwepheshe bokuvelela be-electrode bendabuko bubuchwepheshe bokuvela kwe-arc obungaphansi kwamanzi obunezendlalelo ezimbili onongqimba olushintshayo kanye nongqimba olumelana nokugqwala, kodwa lobu buchwepheshe bunomjikelezo omude wokukhiqiza kanye nezindleko eziphezulu zokukhiqiza. Ukuze kuxazululwe le nkinga, i-JingQunCo ithuthukise izinto zokushisela ezinongqimba olulodwa (i-GDS-309LA umugqa wokushisela, i-GXS-ED308L electroslag flux), engafinyelela umphumela wokuvela kwezendlalelo ezimbili ngokuvela kongqimba olulodwa kuphela, futhi engenza kube lula. inqubo yokuvela phezulu isuka endaweni enezendlalelo ezimbili iye kokungaphezulu kwesendlalelo esisodwa.

Ukwethulwa kwezinto zokushisela

1.Ingxenye yeKhemikhali

| Rules/Igama | C | Si | Mn | P | S | Cr | Ni | Nothi |

| NB/T47018.5 EQ309LA | ≤0.030 | ≤1.00 | 0.5-2.5 | ≤0.025 | ≤0.015 | 21.0-23.0 | 9.0-12.0 | i-solder strip |

| GI-DS-309LA | 0.018 | 0.34 | 1.90 | 0.017 | 0.001 | 21.96 | 11.17 | i-solder strip |

| Rules/Igama | I-NB/T47018.5 FZ308-D | I-GDS-309LA+GXS-ED308L inhlanganisela ye-solder strip + Flux | |||

| C | ≤0.05 | 0.028 | 0.028 | 0.029 | 0.029 |

| Si | ≤1.00 | 0.58 | 0.64 | 0.62 | 0.64 |

| Mn | ≤2.5 | 1.33 | 1.33 | 1.35 | 1.33 |

| P | ≤0.030 | 0.018 | 0.018 | 0.018 | 0.017 |

| S | ≤0.020 | 0.004 | 0.004 | 0.004 | 0.004 |

| Cr | 18.0-21.0 | 18.21 | 18.47 | 18.39 | 18.28 |

| Ni | 8.0-11.0 | 10.12 | 10.31 | 10.27 | 10.30 |

| Qaphela | insimbi ebekiwe | Welding surface | Ngaphansi kobuso 1mm | Ngaphansi kobuso 2mm | Ngaphansi kobuso 3mm |

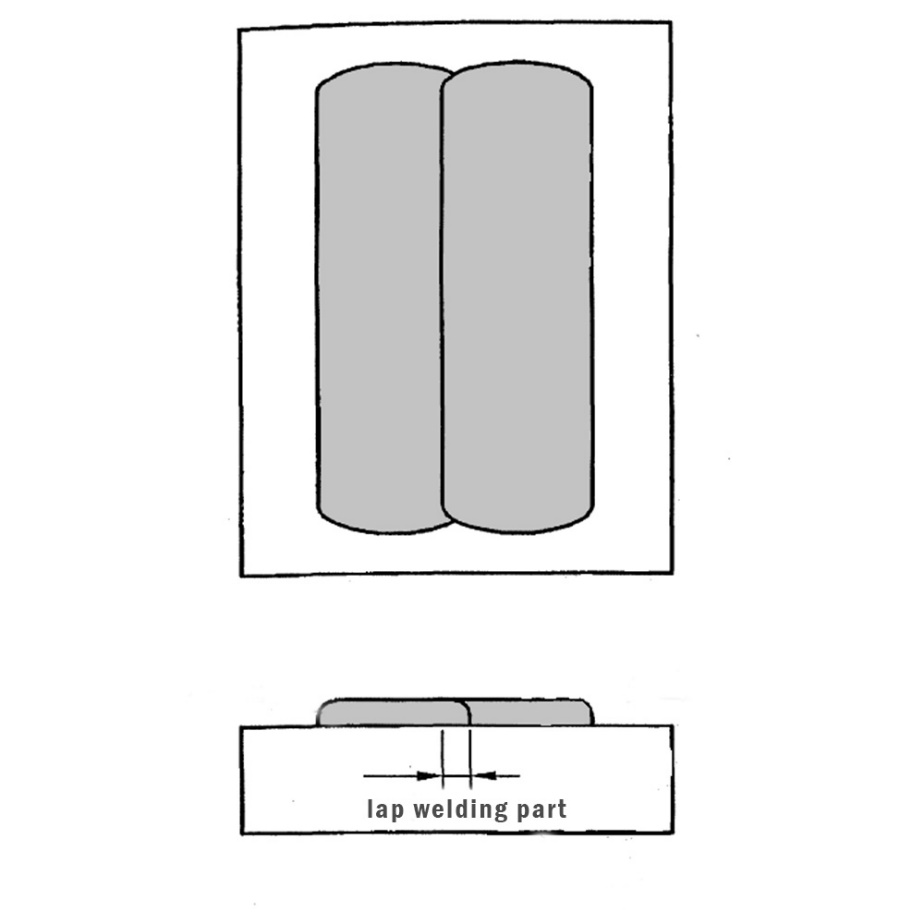

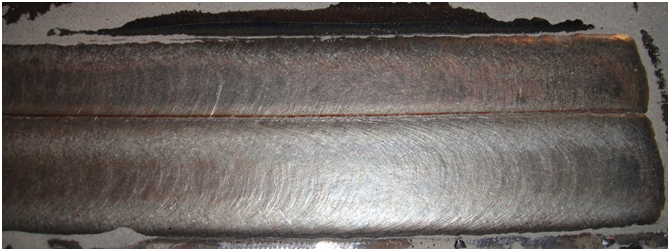

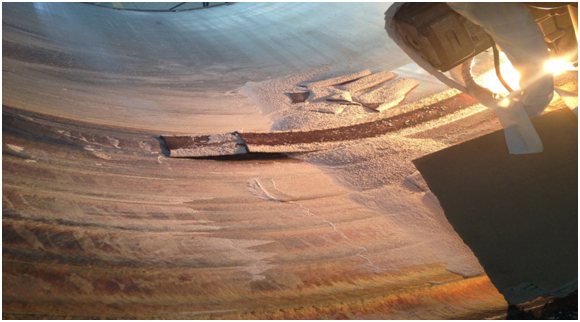

Ukubukeka kwe-2.Weld

Amapharamitha we-welding anconyiwe

| Ukucaciswa(mm) | 0.5*60 |

| Ugesi(A) | 850-950 |

| I-Voltage(V) | 26-30 |

| WIsivinini sokugcina(mm/min) | 150 |

| Lubude(mm) | 35-40 |

| I-Lap welding(mm/min) | 6-10 |

| Ubukhulu bokusakazeka kwe-flux (mm/min) | Aibe 25 |

Ubukhulu be-Weld pass: mayelana ne-4.7mm

Ububanzi be-Weld: mayelana ne-62.5mm

Ukubukeka kwe-weld pass: umumo omuhle, i-weld surface iyisicaba, uguquko lwe-lap lubushelelezi.

3.Umthamo wemishini

Okuqukethwe kwe-Ferrite (isimo esishiselwe)

| Inhlanganisela ye-Solder strip + Flux | GI-DS-309LA+GXS-ED308L |

| Inani elilinganiselwe | Okuqukethwe kwe-ferrite kumayelana ne-7FN, kanti iphesenti le-ferrite licishe libe ngu-8% |

| Indawo yokulinganisa | Indawo yokushisela |

Indlela yokuhlola: GB/T 1954-2008 "chromium-nickel austenitic stainless steel weld ferrite content measurement method"

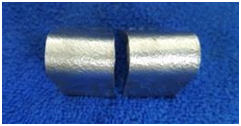

Ukuhlolwa kokugoqa:

as

620℃*20h

Imiphumela yokuhlolwa: ukugoba kwezinhlangothi, ububanzi be-indenter engu-4T (40mm), i-engeli egobayo engu-180° ngaphandle kokuqhekeka.

Ukuhlolwa kokugqwala kwe-Intergranular

Njengoba ezishiselwe

620℃*20h

Indlela yokuhlola: GB/T 4334-2020 Indlela E

Isixazululo sokuhlola: ithusi - sulfate yethusi -16% sulfuric acid

Imiphumela yokuhlolwa: Ayikho i-intergranular corrosion crack

I-Micro metallography yongqimba olungaphezulu

Njengoba ezishiselwe

Njengoba ezishiselwe

620℃*20h ukwelashwa ukushisa

620℃*20h ukwelashwa ukushisa

Isicelo sobunjiniyela

Inqubo yokuhlola inqubo ye-welding ye-1.Customer

2.Ukwakhiwa kwendawo yekhasimende

Ngemuva kweminyaka yocwaningo nentuthuko, ukusebenza kwezinto zokushisela i-Jingqun single-layer electroslag kuzinzile futhi kuthembekile, kunezimpumelelo eziningi zohlelo lobunjiniyela.

Siyakwamukela amakhasimende ukuze uxhumane futhi ukhethe!

Ulwazi olwengeziwe engeza i-whatsapp+86 13252436578

E-Mail:sale@welding-honest.com

Isikhathi sokuthumela: Nov-04-2022