Ngo-2010, i-POSCO yaseNingizimu Korea, i-Daewoo Shipbuilding kanye nezinhlangano ezinhlanu zomhlaba ezinkulu ezihlukanisayo zaqala iphrojekthi "yokuthuthukiswa okuhlangene kwensimbi ephezulu ye-manganese kanye nezinto zokushisela ukuze kugcinwe izinga lokushisa eliphansi kakhulu", futhi bathola ukukhiqizwa kwensimbi ephezulu ye-manganese yamathangi okugcina i-LNG 2015. NgoJuni 2022, ukuze kunqamuke ibhodlela lobuchwepheshe, i-Daewoo Shipbuilding yaseNingizimu Korea & I-Marine Engineering (i-DSME) kanye ne-POSCO izobamba owokuqala emhlabeni ukufaka amathangi okugcina uphethiloli we-manganese ensimbi ephezulu ye-LNG eMkhosini we-LNG-powered very large crude carriers (VLCCs), futhi yathi isithuthukise ubuchwepheshe bokukhiqiza amathangi kaphethiloli kusukela ekusetshenzisweni kwensimbi kuqala. ekushiseni nasekwakheni.

1. Iyini insimbi ephezulu ye-manganese?

Insimbi ephezulu ye-manganese yamathangi okugcina e-LNG iyinsimbi eyingxubevange enokuqukethwe kwe-manganese phakathi kuka-22-25%, enokumelana okuhle kwezinga lokushisa eliphansi nokumelana nokugqoka okuphezulu, okusobala kakhulu kunezinto zethangi lokugcina le-LNG Isithandwa esisha sethangi lokugcina i-LNG. izinto iNingizimu Korea ezinikele ekucwaningeni nasekuthuthukisweni iminyaka engaphezu kweshumi.

2.Ukuhlaziywa kafushane kwezinhlobo zensimbi kanye nezinzuzo kanye nokubi zazo zamathangi okugcina e-LNG Izinto zethu ezisetshenziswayo zokushisela ezihambisanayo zingahlangabezana nalezi zidingo eziqinile: Njengoba amathangi amakhulu okugcina uphethiloli e-LNG eyimishini eyinhloko yemikhumbi enamandla kaphethiloli ehambisana nemvelo kanye nalo lonke uchungechunge lwemboni ye-LNG, izindinganiso zobuchwepheshe ziqinile ngokwedlulele futhi izindleko ziyabiza. I-LNG ivamise ukugcinwa futhi ihanjiswe ngaphansi kwezinga lokushisa eliphansi kakhulu elingu -163°C. “Ikhodi Yamazwe Ngamazwe Yokwakhiwa Nezisetshenziswa Zemikhumbi Ethwala Amagesi Amanzi Ngobuningi” ibizwa ngokuthi “Ikhodi Ye-IGC”. Izinto ezine ezinezinga lokushisa eliphansi ezingasetshenziselwa ukwakha i-LNG zifaka: i-aluminium alloy steel, i-Austria Tensitic stainless steel, i-austenitic Fe-Ni alloy steel (eyaziwa nangokuthi i-Invar steel) ne-9%Ni steel (bona Ithebula 1 ukuze uthole imininingwane), kuyilapho i-9%Ni steel iyona esetshenziswa kakhulu futhi isetshenziswa kabanzi kumathangi okugcina uphethiloli we-LNG. Kodwa ukungalungi ukuthi intengo isephezulu, izinqubo zokucubungula zinzima, amandla aphansi, futhi okuqukethwe kwe-nickel emkhiqizweni kuphezulu. Eminyakeni yamuva, intengo ye-nickel iqhubekile nokukhuphuka, futhi izindleko zomkhiqizo zikhuphuke kakhulu.

Izinto ezi-4 ze-cryogenic ezingasetshenziswa ekwakhiweni kwe-LNG ngaphansi kwe- "IGC Code"

| Izinga lokushisa elincane lokuklama | Izinhlobo zensimbi eziyinhloko nokwelashwa kokushisa | Izinga lokushisa lokuhlola lomthelela |

| -165 ℃ | 9%Ni insimbi ye-NNT noma i-QT | -196℃ |

| insimbi engagqwali ye-austenitic - 304, 304L, 316/316L, 321 kanye nesixazululo esingu-347 siphathwe | -196℃ | |

| I-aluminium alloy - 5083 annealed | NO | |

| i-austenitic iron-nickel alloy (36%Ni) |

Ukuqhathaniswa kwamandla phakathi kwezinto ezisetshenziswa kakhulu ze-LNG nensimbi entsha ye-manganese ephezulu

| Into | Ngokuvamile i-alloy | high manganese steel | ||||

| 9% Insimbi | 304 SS | I-Alu 5083-O | Invar steel | MC | ||

| Izinto eziyisisekelo | Ukwakheka Kwamakhemikhali | Fe-9Ni | Fe-18.5Cr-9.25Ni | I-Al-4.5Mg | Fe-36Ni | M CH |

| I-Microstructure | α1 (+Y) | γ (FCC) | FCC | FCC | FCC | |

| Isivuno AmandlaMpa | ≥585 | ≥205 | 124-200 | 230-350 | ≥400 | |

| Amandla Okuqina Mpa | 690-825 | ≥515 | 276-352 | 400-500 | 800-970 | |

| -196℃UmthelelaJ | ≥41 | ≥41 | NO | NO | ≥41 | |

| Ukushisela | izinto ezisetshenziswayo zokushisela | I-Inconal | Uhlobo308 | ER5356 | - | I-FCA,SA,GTA |

| Isivuno AmandlaMpa | - | - | - | - | ≥400 | |

| Amandla OkuqinaMpa | ≥690 | ≥550 | - | - | ≥660 | |

| -196℃UmthelelaJ | ≥27 | ≥27 | - | - | 27 | |

I-ultra-low-low-high-manganese steel, ehlanganisa amandla aphezulu, ukuqina okuphezulu, kanye nezindleko eziphansi, inethuba elibanzi kakhulu lokusebenzisa ithangi le-LNG lokugcina uphethiloli kanye nokuvikelwa kwemvelo okuhlukile kwezimakethe zamathangi okugcina uphethiloli njenge-ammonia ewuketshezi, i-hydrogen ewuketshezi, kanye ne-methanol.

Izidingo zokwakheka nokusebenza kwensimbi ephezulu ye-manganese

Ukwakhiwa Kwekhemikhali (Okusalungiswa kwe-ASTM)

|

| C | Mn | p | s | Cr | Cu |

| % | 0.35-0,55 | 22.5-25.5 | <0.03 | <0.01 | 3.0-4.0 | 0.3-0.7 |

Ukuziphatha kwemishini

● Isakhiwo sekristalu: i-cubic lattice yobuso emaphakathi (γ-Fe)

● Izinga lokushisa elivumelekile>-196℃

● Amandla esivuno>400MPa (58ksi)

● Amandla e-Tensile: 800~970MPa (116-141ksi)

● Ukuhlolwa komthelela we-Charpy V-notch >41J kokuthi -196℃(-320℉)

Ukwethulwa kwezinto ezisetshenziswayo zenkampani yethu ezisezingeni eliphezulu ze-manganese ezihambisana nokushisela

Eminyakeni yamuva nje, sizinikele ocwaningweni nasekuthuthukisweni kwezinto ezisetshenziswayo zokushisela ezihambisana nensimbi ene-manganese ephezulu yamathangi okugcina e-LNG, kanye nezinto ezisetshenziswayo zokushisela ezithuthukiswe ngempumelelo ezingahambisana nezakhiwo zesisekelo sensimbi ye-manganese ephezulu yamathangi okugcina e-LNG. Izakhiwo ezithile zikhonjiswe kuThebula 2.

Izakhiwo zemishini yensimbi ephezulu ye-manganese ehambisana nezinto zokushisela ezifakiwe zensimbi

| Igama | Isikhundla | izakhiwo zemishini | ||||

| YP | TS | EL | -196 ℃ umthelela | ukuhlolwa kwe-radiographic | ||

| Imigomo yokuklama | ≥400 | ≥660 | ≥25 | ≥41 | I | |

| I-GER-HMA Φ3.2mm | I-electrode eyenziwe ngesandla | 488 | 686 | 46.0 | 73.3 | I |

| I-GCR-HMA-S Φ3.2mm | I-Metal cored wire | 486 | 700 | 44.5 | 62.0 | I |

I-Ps.Metal powder core submerged arc welding wire yensimbi ephezulu yemanganese isebenzisa i-flux GXR-200 ehambisanayo yensimbi ephezulu yemanganese

Ukushisela nokuboniswa kwesampula kwezinto ezisetshenziswayo zokushisela insimbi ye-manganese ephezulu yamathangi okugcina e-LNG

Ukushisela kwezinto ezisetshenziswayo zokushisela zensimbi ephezulu ye-manganese kuboniswa kanje

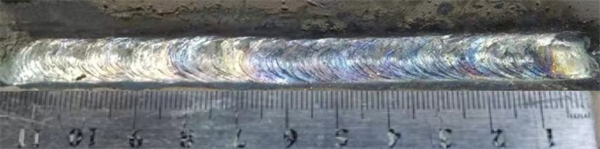

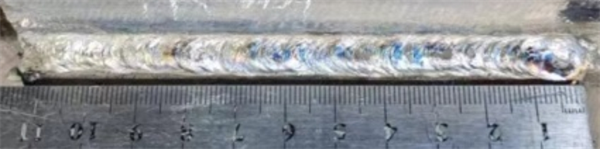

I-Electrode (GER-HMA) i-flat fillet welding ngemva kokususwa kwe-slag

I-Electrode (GER-HMA) yokushisela i-engeli yokuphakama ngemva kokususwa kwe-slag

Induku yokushisela (GER-HMA) ngaphambi nangemva kokususwa kwe-fillet welding slag

Isibonisi se-metal powder core submerged arc (GCR-HMA-S) weld

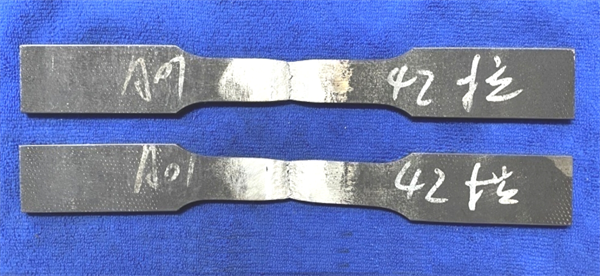

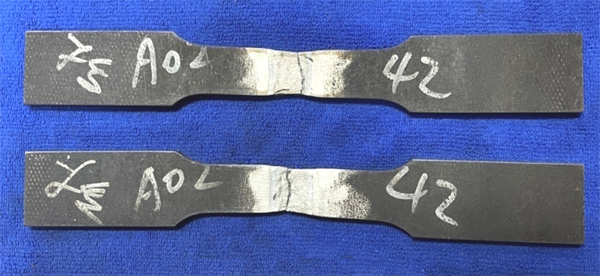

Amasampula amajoyinti okushisela wensimbi ephezulu ye-manganese aboniswa kanje

Isibonisi sesampula se-flat welding (1G) esiqinile

I-Vertical Welding (3G) isibonisi sesampula esiqinile

Isibonisi sesampula sokugoba i-flat welding (1G).

Isibonisi sesampula sokugoba i-flat welding (1G).

I-PS.Insimbi ephezulu yemanganese ishiselwe ngezinduku zokushisela i-1G ne-3G, ayikho imifantu kumasampuli okugoba nomhlane, futhi ukumelana nokuqhekeka kuhle.

Isikhathi sokuthumela: Nov-22-2022