Iwebhusayithi: www.welding-honest.com +8613252736578

I-aluminium ehlanzekile iyinsimbi ethambile futhi edonsa kahle. Ezimweni eziningi, amandla ayo aphansi. Ukwandisa amandla e-aluminium, izakhi ze-alloying zidinga ukungezwa. Ithusi, i-silicon, i-manganese, i-magnesium, ne-zinc kusetshenziswa njengesakhi esiyinhloko ukuze kudlale umphumela wokuqinisa oncibilikayo. I-aluminium ne-aluminium alloy isetshenziswe kabanzi ezimbonini eziningi.

Ukushisela kwe-aluminium ne-aluminium alloy kunzima kakhulu kunensimbi ye-low-carbon steel. Izici zayo zokushisela zihlukile kune-low-carbon steel. Ukusebenza okuqondile kungokulandelayo:

1. I-Soferality ye-welded yokuxhuma ukusebenza kwemishini, yehla ukumelana nokugqwala.

2. Umsebenzi wamakhemikhali unamandla kakhulu, futhi ingaphezulu lakheka kalula.

3. I-conductivity eqinile yokushisa, futhi kulula ukubangela into engancibiliki ngesikhathi sokushisela.

4. Amaphutha alandelanayo njengama-pores, imifantu, imiphetho yokuluma, i-slag kanye nokwakheka kwe-weld.

5. I-coefficient yokwandisa umugqa omkhulu (cishe izikhathi ezi-2 kune-low-carbon steel), ethambekele ekujikeni nasekushintsheni ngesikhathi sokushisela.

6. I-conductivity eshisayo inkulu (cishe izikhathi ezi-5 kune-low-carbon steel). Ngejubane elifanayo lokushisela, okokufaka okushisayo kuphindwe izikhathi ezi-2 kuya kwezi-4 kunensimbi yokushisela.

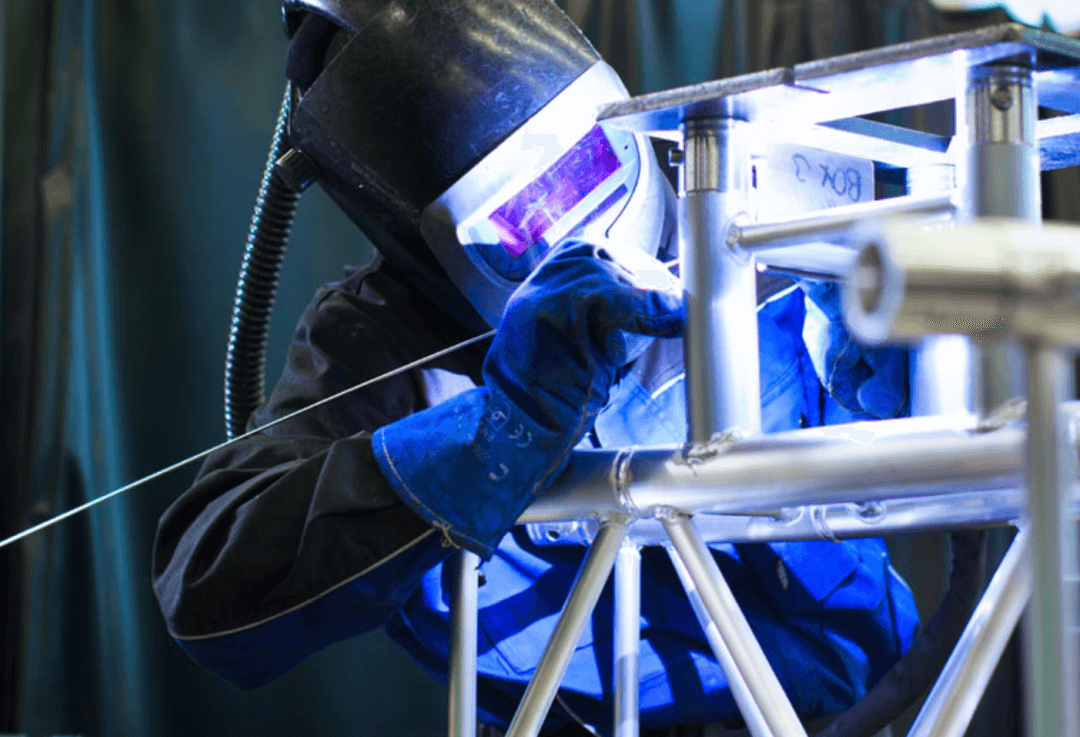

Ingxubevange ye-aluminium ishiselwe nge-TIG noma i-GMAW.

1.I-Aluminium alloy tig welding

Uma udinga ukuthola i-welding yekhwalithi ephezulu kakhulu, i-Tig welding ngokuvamile iyisinqumo sokuqala. Indlela yenqubo efaneleke kakhulu ukushintshanisa i-TIG welding kanye ne-AC pulse TIG welding. Kunezinzuzo eziningana:

1. Lapho i-welding, izici ze-cathode atomization zingasuswa ngokwazo.

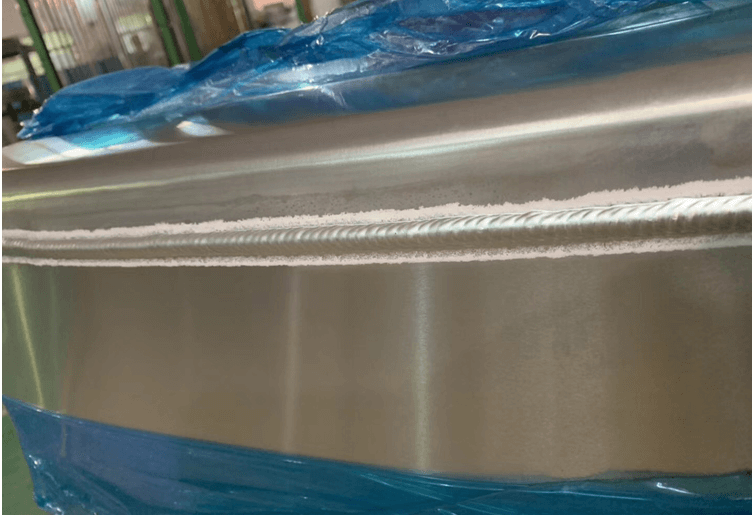

2. Ifomu lokuxhuma alikhawulelwe, indawo engaphezulu ibushelelezi futhi ilungele ukubunjwa.

3. Indawo yokushisela yokugeleza komoya ukupholisa amalunga ukuze kuphole phansi futhi kuthuthukiswe inhlangano nokusebenza.

Ngakho-ke, le nqubo ifaneleka kakhulu embonini ye-aerospace esezingeni eliphezulu futhi ebaluleke kakhulu. Yiqiniso, ukuntula kwayo nakho kusobala kakhulu. Ukusebenza kahle kwe-welding kuphansi, futhi akufanelekile ukukhiqizwa kokusebenza okuphezulu okuphezulu.

1.I-Aluminium ingxubevange ye-GMAW yokushisela

I-Gmaw welding ingene kancane kancane ezimpilweni zethu. Ukuxhumeka kwe-DC reverse kuvame ukusetshenziswa ngesikhathi sokushisela, futhi i-pulse welding nayo ingasetshenziswa. Uma kuqhathaniswa nokushisela kwe-TIG, ukushisela kwe-GMAW kunezinzuzo ezilandelayo:

1. Cishe akukho ukushiswa kwe-oxidative phakathi nenqubo yokushisela, futhi inqubo ilula.

2. Ukukhiqiza okuphezulu kwabasebenzi.

3. Ungathathi izigxobo ze-tungsten, izindleko eziphansi.

Lapho ushisela ku-GMAW, naka amaphuzu alandelayo:

1. Udinga ukusebenzisa ipayipi likasilika elisekelwe epulasitiki, futhi ipayipi lensimbi alikwazi ukusetshenziswa.

2. Intambo yokushisela i-aluminium ithambile futhi ukulethwa kwezintambo kubi. Udinga ukukhetha isondo lokudiliva le-U-shaped groove wire.

3. Sebenzisa i-diameter yangaphakathi yomlomo we-conductive efanele.

4. Ungahlanganyeli izingxenye nge-welding yensimbi ukuze ugweme ukungcola.

I-GMA-A5356 isebenzisa umthelela kusayithi lekhasimende

Le datha yabelana nabasebenzisi abasaqhubeka noma abasazoshiselwa, okusivumela ukuthi sithuthuke emgwaqeni wokushisela i-aluminium alloy.

Imikhiqizo evamile yokuhlinzeka yenkampani yethu imi kanje:

I-TIG MIG

I-GTA-A4043 GMA-A4043

I-GTA-A5183 GMA-A5183

I-GTA-A5356 GMA-A5356

Isikhathi sokuthumela: Nov-14-2022