Ngesikhathi senqubo yokuqina, ukuqhekeka kuvame ukudala izinkinga ezifana nokusebenza kabusha kanye nokubuyiselwa kwamakhasimende. I-Hardfacing surface ihluke ekushiseleni okujwayelekile kwesakhiwo, futhi indlela yokwahlulela nokunaka kwemifantu nakho kuhluke kakhulu. Lesi sihloko sihlaziya futhi sidingida ukubukeka okuvamile kwemifantu kunqubo yokufaka i-surface ukumelana nokugqokwa okuqinile.

1. Ukunqunywa kwemifantu

Njengamanje, ekhaya ngisho nakwamanye amazwe, alikho izinga elijwayelekile lokuqhekeka okubangelwa ukugqokwa kwendawo eqinile. Isizathu esiyinhloko ukuthi kunezinhlobo eziningi kakhulu zezimo zokusebenza zemikhiqizo egqokwayo eqinile, futhi kunzima ukuchaza indlela yokwahlulela esebenzayo esebenzayo ngaphansi kwemibandela. Kodwa-ke, ngokokuhlangenwe nakho ekusetshenzisweni kwezinto zokushisela ezibhekene nokuqina emikhakheni ehlukahlukene, ama-crack degrees amaningana angahlelwa cishe, kanye nezindinganiso zokwamukelwa ezimbonini ezihlukahlukene:

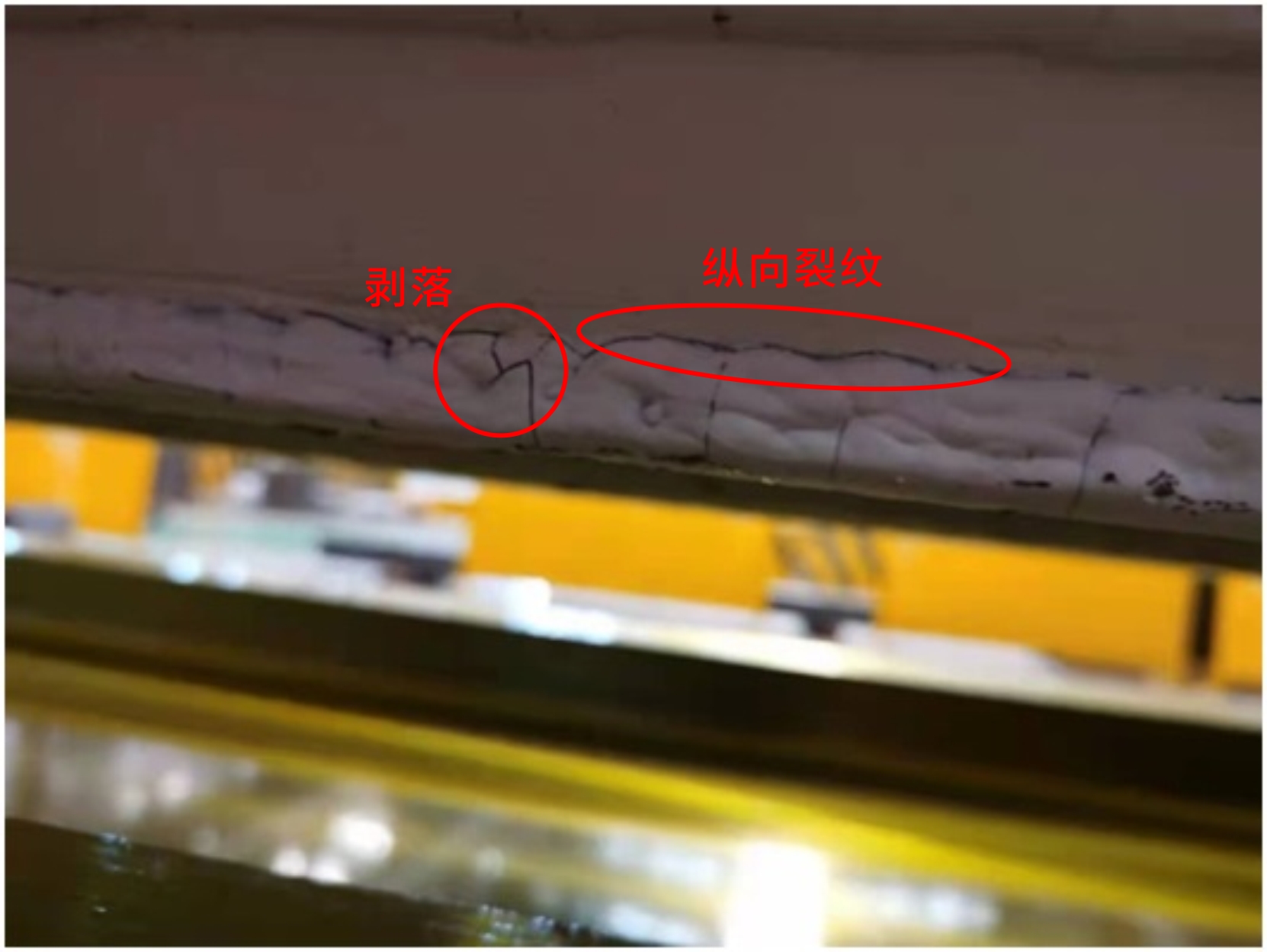

1. Indlela yokuqhekeka ihambisana nobuhlalu obushiselwe (ukuqhekeka kwe-longitudinal), ukuqhekeka okuqhubekayo, ukuqhekeka okudlulela kusisekelo sensimbi, ukugoqa

Uma nje elinye lalawa mazinga okufafazeka ashiwo ngenhla lifinyelelwa, kunobungozi bokuthi lonke ungqimba olungaphezulu luzowa. Ngokuyisisekelo, kungakhathaliseki ukuthi isicelo somkhiqizo siyini, akwamukeleki futhi singasetshenzwa kabusha futhi sidayiswe kabusha.

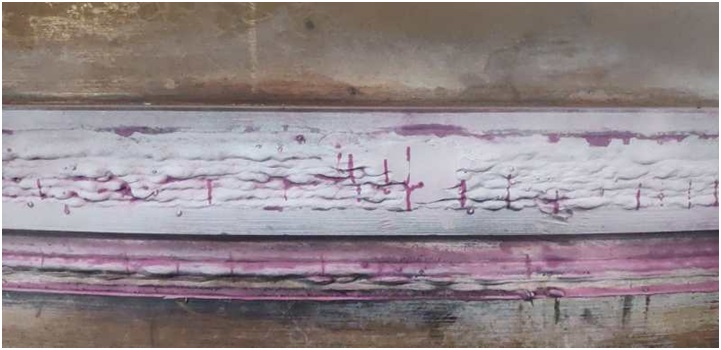

2. Kukhona kuphela imifantu ephambanayo kanye nokungaqhubeki

Ezindaweni zokusebenza ezixhumene nezinto eziqinile ezifana ne-ore, i-sandstone, nezimayini zamalahle, ubulukhuni budingeka bube buphezulu (i-HRC 60 noma ngaphezulu), futhi izinto zokushisela ezine-chromium ephezulu zivame ukusetshenziselwa ukushisela phezulu. Amakristalu e-chromium carbide akhiwe ku-weld bead azokhiqizwa ngenxa yokukhululwa kwengcindezi. Imifantu yamukelekile inqobo nje uma i-crack direction incike kuphela kubuhlalu obushiselayo (transverse) futhi ayiqhubeki. Kodwa-ke, inani lemifantu lisazosetshenziswa njengereferensi yokuqhathanisa izinzuzo nezingozi zezinto ezisetshenziswayo zokushisela noma izinqubo zokuvula.

3. Abukho ubuhlalu be-crack weld

Ezingxenyeni zokusebenza ezifana nama-flange, ama-valve, namapayipi, lapho izinto ezithintana kakhulu namagesi noketshezi, izimfuneko zokuqhekeka kobuhlalu obushiselayo ziqaphe kakhulu, futhi ngokuvamile kudingeka ukuthi ukubukeka kwe-weld bead akufanele kube nemifantu.

Ukuqhekeka okuncane ebusweni bezinto zokusebenza njengama-flange nama-valve kudinga ukulungiswa noma kusetshenzwe kabusha

Sebenzisa i-valve yenkampani yethu ye-GFH-D507Mo ekhethekile yokushisela izinto ezisetshenziswayo ukuze udlulele phezulu, akukho mifantu ebusweni.

2. Izimbangela eziyinhloko zemifantu engaphandle eqinile engagugi

Ziningi izinto ezidala imifantu. Ukuze uthole ukushisela okuqinile kokumelana nokugqokwa kwe-surfacing, ingahlukaniswa ngokuyinhloko ibe imifantu eshisayo engatholakala ngemva kokudlula kokuqala noma kwesibili, kanye nemifantu ebandayo evela ngemva kokudlula kwesibili noma ngisho nangemva kwayo yonke i-welding.

I-Hot crack:

Ngesikhathi senqubo yokushisela, insimbi emthungoni we-weld kanye nendawo ethinteke ukushisa iphola endaweni yokushisa ephezulu eduze komugqa we-solidus ukukhiqiza imifantu.

Ukuqhekeka okubandayo:

Imifantu ekhiqizwa emazingeni okushisa angaphansi kwe-solidus (cishe izinga lokushisa lensimbi lokuguqulwa kwe-martensitic) ikakhulukazi ivela ezinsimbi ze-carbon-carbon kanye nezinsimbi ezinama-low-alloy eziqinile kanye nezinsimbi ze-alloy ephakathi.

Njengoba igama liphakamisa, imikhiqizo yendawo eqinile iyaziwa ngobulukhuni bayo obuphezulu. Kodwa-ke, ukuphishekela ubulukhuni kumakhenikha nakho kuholela ekwehleni kwepulasitiki, okungukuthi, ukwanda kwe-brittleness. Ngokuvamile, ukuvela ngaphezulu kwe-HRC60 akunaki kakhulu imifantu eshisayo ekhiqizwa ngesikhathi senqubo yokushisela. Kodwa-ke, i-welding eqinile enobulukhuni obuphakathi kwe-HRC40-60, uma kunesidingo sokuqhekeka, Ukuqhekeka kwe-intergranular enqubweni yokushisela noma i-liquefaction kanye nemifantu ehlangene ebangelwa ubuhlalu obuphezulu be-weld endaweni ethinteke ukushisa ye-weld ephansi. ubuhlalu buyinkinga kakhulu.

Ngisho noma inkinga yemifantu eshisayo ilawulwe kahle, usongo lokuqhekeka okubandayo lusazobhekana nalo ngemva kokushisela, ikakhulukazi izinto eziphukayo kakhulu njenge-hard surface weld bead, ezwela kakhulu emifantwini ebandayo. Ukuqhekeka okukhulu kubangelwa kakhulu imifantu ebandayo

3. Izinto ezibalulekile ezithinta imifantu engagugi ezindaweni eziqinile namasu okugwema imifantu

Izici ezibalulekile ezingahlolwa lapho ukuqhekeka kwenzeka enqubweni yokugqokwa kwendawo eqinile zimi kanje, futhi kuhlongozwa amasu ahambisanayo esicini ngasinye ukuze kuncishiswe ubungozi bokuqhekeka:

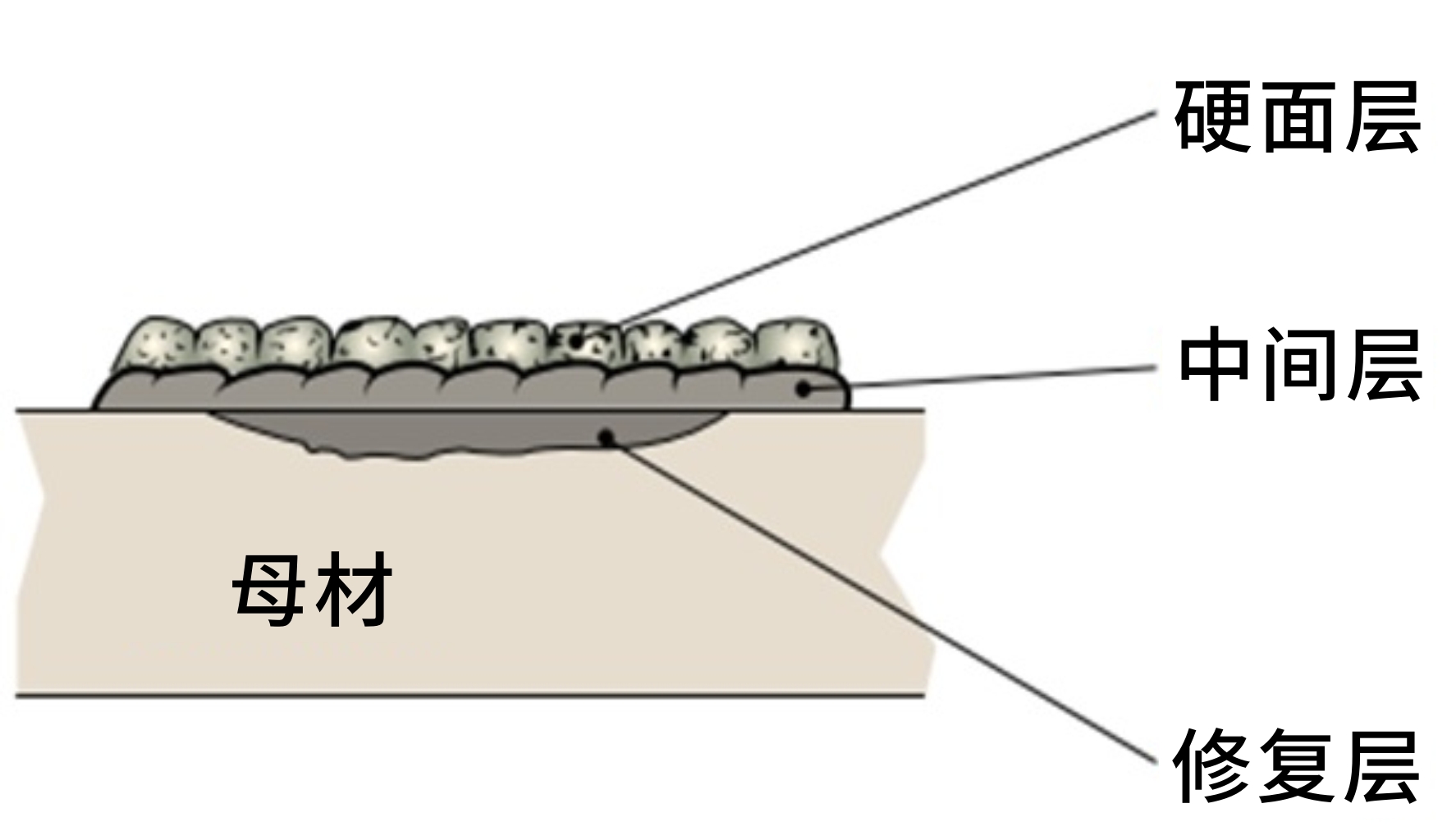

1. Izinto eziyisisekelo

Umthelela wensimbi eyisisekelo endaweni eqinile engagugi ibaluleke kakhulu, ikakhulukazi ezintweni zokusebenza ezinezendlalelo ezingaphansi kwezi-2 zokushisela okungaphezulu. Ukwakheka kwensimbi eyisisekelo kuthinta ngqo izakhiwo ze-weld bead. Ukukhetha izinto ezibonakalayo kuyimininingwane okudingeka inakwe ngaphambi kokuqala umsebenzi. Isibonelo, uma i-valve workpiece enobunzima obuqondiwe obucishe bube yi-HRC30 idlula ngesisekelo sensimbi ecijile, kutuswa ukusebenzisa impahla yokushisela enobulukhuni obuncane obuncane, noma wengeze ungqimba olumaphakathi lwensimbi engagqwali, ukuze gwema okuqukethwe kwekhabhoni kokuyisisekelo ekwenyuseni ubungozi bokuqhekeka kwe-weld bead.

Engeza isendlalelo esimaphakathi kokuyisisekelo ukuze unciphise ingozi yokuqhekeka

2. Izinto ezisetshenziswayo zokushisela

Ngenqubo engadingi ukuqhekeka, izinto zokushisela ezinekhabhoni ephezulu kanye ne-high-chromium azifaneleki. Kunconywa ukusebenzisa izinto zokushisela zesistimu ye-martensitic, njenge-GFH-58 yethu. Ingakwazi ukushisela indawo yobuhlalu obungenamifantu lapho ubulukhuni buphezulu njenge-HRC58~60, ifaneleka ikakhulukazi izingcezu zokusebenza ezingahleliwe ezihuzuka kakhulu inhlabathi namatshe.

3. Ukushisa okokufaka

Ukwakhiwa kwendawo kuvame ukusebenzisa amandla aphezulu kanye ne-voltage ngenxa yokugcizelela ekusebenzeni kahle, kodwa ukwehlisa ngokulinganisela amandla amanje kanye ne-voltage nakho kunganciphisa ngempumelelo ukwenzeka kwemifantu eshisayo.

4. Ukulawula izinga lokushisa

I-Multi-layer kanye ne-multi-pass hardfacing welding ingathathwa njengenqubo yokushisisa okuqhubekayo, ukupholisa nokufudumeza kabusha kwephasi ngayinye, ngakho-ke ukulawulwa kwezinga lokushisa kubaluleke kakhulu, kusukela ekushiseni ngaphambi kokushisela ukuze kudlule izinga lokushisa ngesikhathi sokulawula okungaphezulu, ngisho nenqubo yokupholisa ngemva kwalokho. i-welding, idinga ukunakwa okukhulu.

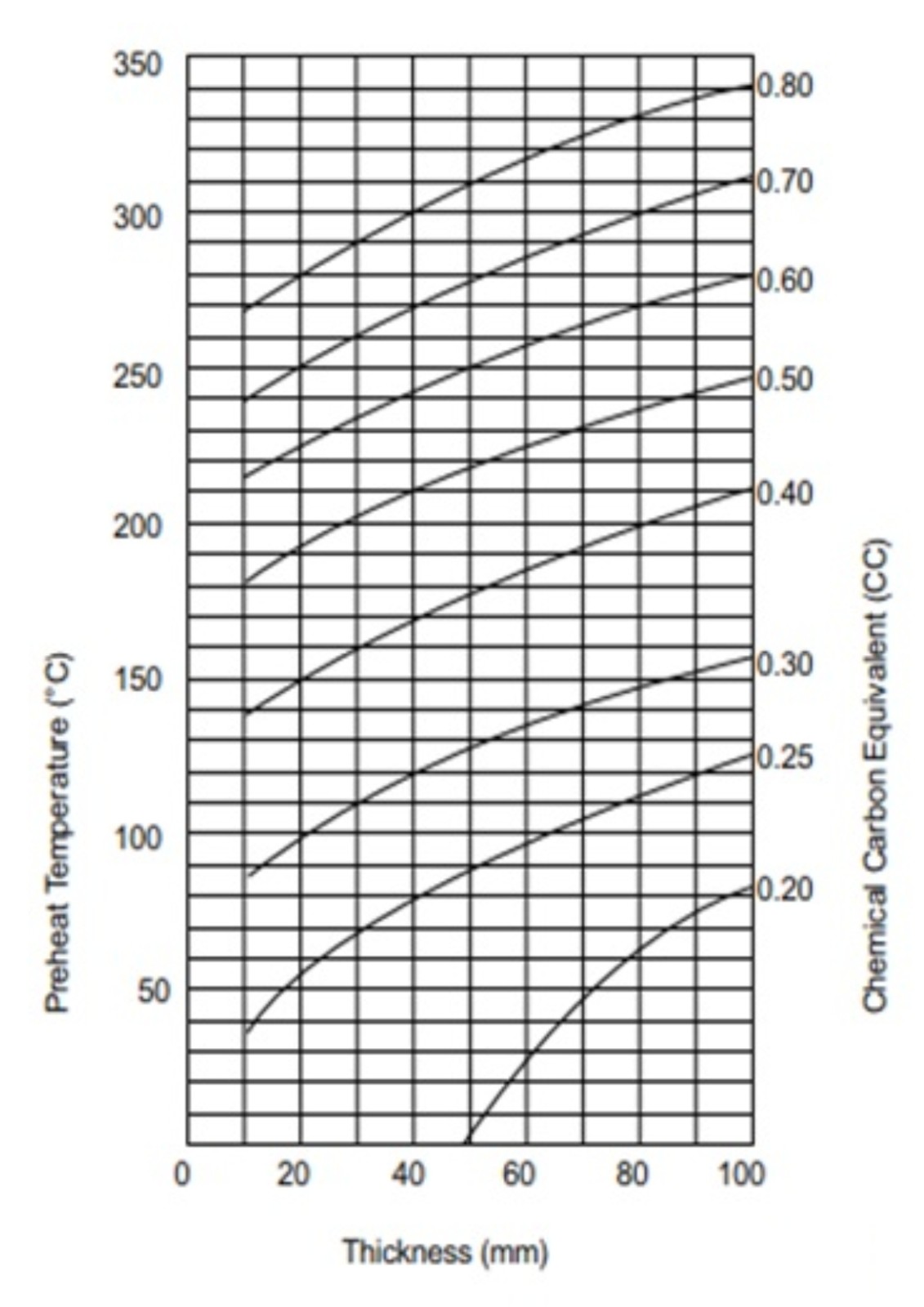

Ukushisa kwangaphambili kanye nokulandelela izinga lokushisa lokushisela okungaphezulu kuhlobene kakhulu nokuqukethwe kwekhabhoni ye-substrate. I-substrate lapha ihlanganisa izinto eziyisisekelo noma isendlalelo esiphakathi, kanye nephansi lendawo eqinile. Ngokuvamile, ngenxa yokuqukethwe kwekhabhoni yensimbi efakwe endaweni eqinile Uma okuqukethwe kuphezulu, kunconywa ukugcina izinga lokushisa lomgwaqo ngaphezu kwama-degree angu-200. Kodwa-ke, ekusebenzeni kwangempela, ngenxa yobude obude be-weld bead, ingxenye engaphambili ye-weld bead ipholile ekupheleni kwephasi eyodwa, futhi iphasi yesibili izokhiqiza kalula imifantu endaweni ethinteke ukushisa ye-substrate. . Ngakho-ke, lapho kungabikho imishini efanele yokugcina izinga lokushisa lesiteshi noma ukushisa kuqala ngaphambi kokushiswa, kunconywa ukuthi kusebenze ezingxenyeni eziningi, ama-welds amafushane, kanye ne-welding eqhubekayo eqhubekayo esigabeni esifanayo ukuze kugcinwe izinga lokushisa lesiteshi.

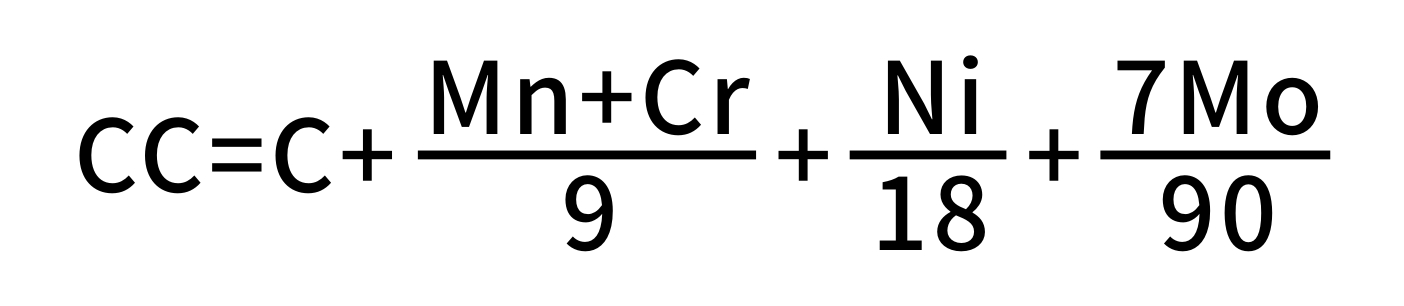

Ubudlelwano phakathi kokuqukethwe kwekhabhoni nezinga lokushisa elishisa ngaphambili

Ukupholisa okunensayo ngemva kokuvela futhi kuyisinyathelo esibucayi kakhulu kodwa esivame ukunganakwa, ikakhulukazi ezintweni ezinkulu zokusebenza. Kwesinye isikhathi akulula ukuba nezinto ezifanele zokuhlinzeka ngezimo zokupholisa ezihamba kancane. Uma ngempela ingekho indlela yokuxazulula lesi simo, singancoma kuphela ukuthi siyisebenzise futhi Indlela yokusebenza ngokwezigaba, noma ugweme ukushisela okungaphezulu lapho izinga lokushisa liphansi, ukunciphisa ingozi yokuqhekeka okubandayo.

Ezine. Isiphetho

Kusenomehluko omningi wabakhiqizi abangabodwana ezidingweni zokuqinisa ukuze kuqhekeke izinhlelo zokusebenza ezingokoqobo. Lesi sihloko senza kuphela ingxoxo enzima esekelwe kokuhlangenwe nakho okulinganiselwe. Uchungechunge lwenkampani yethu oluqinile olumelana nokugqokwa kwezinto ezisetshenziswayo zokushisela lunemikhiqizo ehambisanayo ukuze amakhasimende ayikhethele ubulukhuni obuhlukahlukene kanye nezinhlelo zokusebenza. Siyakwamukela ukuthintana nebhizinisi esifundeni ngasinye.

Ukusetshenziswa kwefekthri yebhodi eyinhlanganisela engagugi

| Into | Vikela igesi | usayizi | Okuyinhloko | HRC | Ukusebenzisa |

| GFH-61-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 ISi:0.6 UMb:1.2 IsiKr:28.0 | 61 | Ifanele amasondo okugaya, izixube zikasimende, ama-bulldozer, njll. |

| GFH-65-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 IsiKr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | Ifanele izinga lokushisa eliphezulu lokususa uthuli ama-fan blades, imishini yokuphakela isithando somlilo, njll. |

| I-GFH-70-O | Zivikele | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | Isebenza kurola wamalahle, i-ghost red, igiya lokwamukela, ikhava yamalahle eqhumayo, umshini wokugaya, njll. |

Isicelo embonini usimende

| Into | Vikela igesi | usayizi | Okuyinhloko | HRC | Ukusebenzisa |

| GFH-61-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 ISi:0.6 UMb:1.2 IsiKr:28.0 | 61 | Ifanele ukugaya ama-roller amatshe, izixube zikasimende, njll |

| GFH-65-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 IsiKr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | Ifanele izinga lokushisa eliphezulu lokususa uthuli ama-fan blades, imishini yokuphakela isithando somlilo, njll. |

| I-GFH-70-O | Zivikele | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | Ifanele ukugaya ama-roller amatshe, amazinyo ayisipoki, amazinyo okwamukela, ama-grinders, njll. |

| I-GFH-31-S | GXH-81 | 2.8 3.2 | C:0.12 ISi:0.87 UMb:2.6 Mo:0.53 | 36 | Isebenza ezingxenyeni zokugqoka zensimbi ukuya kwensimbi njengamasondo omqhele nama-ekseli |

| I-GFH-17-S | GXH-81 | 2.8 3.2 | C:0.09 Ibe:0.42 UMb:2.1 IsiKr:2.8 Mo:0.43 | 38 | Isebenza ezingxenyeni zokugqoka zensimbi ukuya kwensimbi njengamasondo omqhele nama-ekseli |

Steel Plant Isicelo

| Into | Vikela igesi | usayizi | Okuyinhloko | HRC | Ukusebenzisa |

| GFH-61-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 ISi:0.6 UMb:1.2 IsiKr:28.0 | 61 | Ifanele imigoqo yesithando somlilo esishisayo, amazinyo esipoko, amapuleti angagugi, njll. |

| GFH-65-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 IsiKr:22.5 Mo:3.2 V:1.1 W:1.368 Nb:3.5 | 65 | |

| I-GFH-70-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | |

| I-GFH-420-S | GXH-81 | 2.8 3.2 | C:0.24 ISi:0.65 UMb:1.1 IsiKr:13.2 | 52 | Ifanele amaroli asakazayo, amaroli adlulisayo, amaroli esiteringi, njll. ezitshalweni zokusakaza eziqhubekayo nezitshalo ezigoqayo ezishisayo |

| I-GFH-423-S | GXH-82 | 2.8 3.2 | C:0.12 Ibe:0.42 UMb:1.1 IsiKr:13.4 Mo:1.1 V:0.16 Isiqephu:0.15 | 45 | |

| I-GFH-12-S | GXH-81 | 2.8 3.2 | C:0.25 Ibe:0.45 Mnu:2.0 IsiKr:5.8 Mo:0.8 V:0.3 W:0.6 | 51 | Izakhiwo zokugqokwa kwe-anti-adhesive, ezifanele amaroli wefekthri ye-steel plate, ncinza amaroli kanye nezingxenye zokugqokwa phakathi kwezinsimbi |

| I-GFH-52-S | GXH-81 | 2.8 3.2 | C:0.36 ISi:0.64 Mnu:2.0 Kusukela:2.9 IsiKr:6.2 Mo:1.35 V:0.49 | 52 |

Isicelo somvukuzi

| Into | Vikela igesi | usayizi | Okuyinhloko | HRC | Ukusebenzisa |

| GFH-61-0 | Zivikele | 1.6 2.8 3.2 | C:5.0 ISi:0.6 UMb:1.2 IsiKr:28.0 | 61 | Isebenza kuma-excavators, izihloko zomgwaqo, amapiki, njll. |

| GFH-58 | CO2 | 1.6 2.4 | C:0.5 ISi:0.5 Mnu:0.95 Kusukela:0.03 IsiKr:5.8 Mo:0.6 | 58 | Ifanele ukushisela i-surfacing eceleni kwe-trough yokulethwa kwamatshe |

| I-GFH-45 | CO2 | 1.6 2.4 | C:2.2 ISi:1.7 Mnu:0.9 IsiKr:11.0 Mo:0.46 | 46 | Ifanele ukugqoka izingxenye phakathi kwezinsimbi |

Isicelo se-valve

| Into | Vikela igesi | usayizi | Okuyinhloko | HRC | Ukusebenzisa |

| I-GFH-D507 | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mnu:0.4 Kusukela:0.1 IziKr:13 Mo:0.01 | 40 | Ifanele ukushisela okungaphezulu kwe-valve sealing surface |

| I-GFH-D507Mo | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mnu:0.4 Kusukela:0.1 IziKr:13 Mo:0.01 | 58 | Ifanele ukushisela ama-valve anokugqwala okuphezulu |

| I-GFH-D547Mo | Izinduku zezandla | 2.6 3.2 4.0 5.0 | C:0.05 UMb:1.4 ISi:5.2 P:0.027 S:0.007 Kusukela:8.1 IsiKr:16.1 Mo:3.8 Isiqephu:0.61 | 46 | Ifanele izinga lokushisa eliphezulu, i-valve ephezulu yokucindezela i-surfacing welding |

More information send to E-mail: export@welding-honest.com

Isikhathi sokuthumela: Dec-26-2022