I. Uhlolojikelele

Ngokuthuthuka okusheshayo kokukhiqizwa kwemboni yemishini, izakhiwo ezishiselwe njengobunjiniyela besimanje kanye nemikhumbi yokucindezela ziyathuthuka zibheke kuzitayela ezikhulayo nezingasindi. Izidingo zamabanga amandla ensimbi ziya ngokuya zikhuphuka, azidingi nje kuphela izici ezinhle zokusebenza eziphelele, kodwa futhi nokucutshungulwa okuhle, ukushisela kanye nokumelana nokuqhekeka.

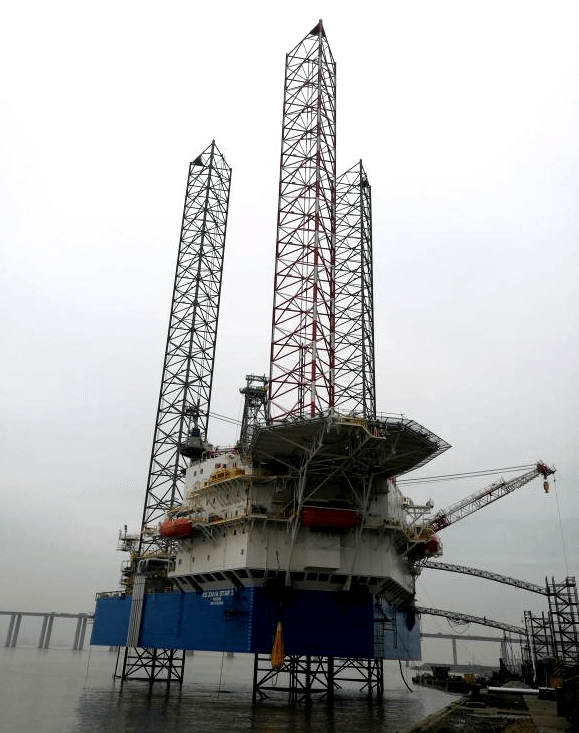

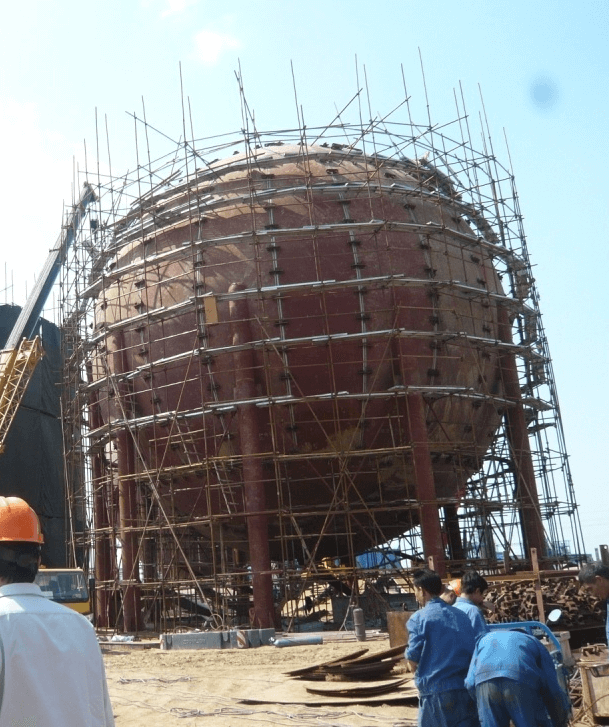

Insimbi ye-Q690 ingeyensimbi yesakhiwo esishiselwe amandla aphezulu, lapho i-Q imele isivuno, futhi u-690 usho ukuthi izinga lamandla esivuno lingu-690MPa. Insimbi yezinga le-690MPa inesivuno esikhulu namandla aqinile, futhi isetshenziswa kabanzi emishinini yezimayini zamalahle, imishini yokwakha, ubunjiniyela basolwandle, amapulatifomu asogwini lolwandle, imikhumbi yokucindezela, njll., edinga insimbi ukuthi ibe namandla okukhiqiza aphezulu kanye nomkhawulo wokukhathala, ukuqina komthelela omuhle, Ukubanda. formability kanye weldability omuhle kakhulu.

2.Isingeniso esifushane se-Q690 steel plate

| Amazwe ngamazwe Ibanga lensimbi le-Q690 | Q690A | Q690B | Q690C | Q690D | Q690E | Q690F |

| Uphaphe | Okushisayo kugoqiwe | Ukucisha + ukuthukuthela (isimo esicishiwe nesithambile) | ||||

| Okuqukethwe ukungcola | Inani eliphakeme kakhulu lama-P/S | i-P/S ephansi | I-P/S encane | |||

| Izidingo Zokushaqeka | NO | Ukushaqeka kwezinga lokushisa elivamile | 0℃ | -20 ℃ | -40 ℃ | -60 ℃ |

Kodwa-ke, okwamanje, ipuleti lensimbi elingu-690MPa lemikhumbi yengcindezi yasekhaya lisekelwe ikakhulukazi ku-EN10028-6 ejwayelekile yaseYurophu, futhi izakhiwo ezifanele zibalwe kafushane kuthebula elilandelayo:

| Hola insimbi engu-690MPA yemishini yokucindezela evamile yaseYurophu | P690Q | I-P690QH | I-P69QL1 | I-P69QL2 |

| Uphaphe | okusanhlamvu okuhle okucinyiwe kanye nensimbi epholile | |||

| izidingo zamandla | Yield≥690MPa(plate thickness≤50mm) Tensile770-940MPa | |||

| Okuqukethwe ukungcola | P≤0.025%,S≤0.015% | P≤0.02%,S≤0.010% | ||

| Izidingo Zokushaqeka | 20℃≥60J | 20℃≥60J | 0℃≥60J | -20℃≥40J |

| 0℃≥40J | 0℃≥40J | -20℃≥40J | -40℃≥27J | |

| -20℃≥27J | -20℃≥27J | -40℃≥27J | -60℃≥27J | |

| Izindawo zokufaka izicelo eziyinhloko | Izakhiwo ezithwala ingcindezi noma imikhumbi yokucindezela enezidingo zokuqina komthelela ophansi | Ithangi eliyindilinga elinezidingo eziphezulu zobuchwepheshe | I-liquefied gas marine liquid tank | |

Njengepuleti lensimbi lamathangi okugcina kanye nomthamo wokucindezela, kufanele libe namandla amahle nokuqina, ukusebenza kokugoba okubandayo kanye nokuzwela kokuqhekeka okuphansi. Nakuba insimbi ecishiwe futhi eqinile ye-Q690 inokulingana nekhabhoni ephansi kanye nezakhiwo ezinhle kakhulu ezihlanganisayo, isenomkhuba othile wokuqina uma iqhathaniswa nezinye izinsimbi zomkhumbi we-50/60kg, futhi ukwelashwa kokushisa kwangemuva kwe-weld kuyadingeka. Kodwa-ke, inani elikhulu locwaningo lokuhlola libonise ukuthi ezintweni ezisetshenziswayo zokushisela insimbi ye-Q690, ukuqina komthelela wezinga lokushisa eliphansi kuzowohloka kakhulu ngemva kokwelashwa kokushisa kokunciphisa ingcindezi, kanye nokwenyuka kwezinga lokushisa lokwelashwa nokuncipha kwezinga lokushisa lomthelela, ukuwohloka. wokushisela ukuqina okusetshenziswayo kuzoba sobala kakhulu. Ngakho-ke, kubaluleke kakhulu ukuthuthukisa amandla aphezulu, ukuqina okunomthelela omkhulu, kanye nezinduku zokushisela ezikwazi ukumelana nokushisa zensimbi ye-Q690 ukuze kusetshenziswe ngempumelelo insimbi ye-Q690 emishinini ethwala ingcindezi, ukunciphisa izinto zensimbi, nokunciphisa izindleko zokukhiqiza.

3.Ukwethulwa kafushane kwenduku yethu yokushisela insimbi ye-Q690

| Into | Okujwayelekile | Uhlobo lwesikhumba | I-polarity | izici eziyinhloko |

| I-GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | I-iron powder uhlobo oluphansi lwe-hydrogen | I-DC+/AC | Amandla aphezulu, i-hydrogen ephansi, ukusebenza kahle kwe-deposition ephezulu, izakhiwo ezizinzile zemishini, izinga lokushisa eliphansi eliqine kakhulu libe ngu-50°C, nokuqina komthelela omuhle ku--40°C ngemva kokwelashwa kokushisa. |

| I-GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | I-iron powder uhlobo oluphansi lwe-hydrogen | I-DC+/AC | I-hydrogen ephansi kakhulu, ukusebenza kahle kokubekwa okuphezulu, ukuqina okuphezulu (-60℃≥70J), ukuqina komthelela omuhle kokuthi -40/-50℃ ngemva kokwelashwa kokushisa |

| I-GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Uhlobo oluphansi lwe-hydrogen potassium | I-AC/DC+ | I-hydrogen ephansi kakhulu, i-AC/DC+ injongo ekabili, ukuqina komthelela omkhulu (-60℃≥70J), ukuqina komthelela omuhle kokuthi -50/-60℃ ngemva kokwelashwa kokushisa |

4.Q690 insimbi yokushisela induku yokubonisa ukusebenza komshini

| Into | As-welded mechanical izakhiwo | ||||||

| Khipha i-MPA | Tensile MPA | Nweba % | Isakhiwo somthelela J/℃ | Ukuhlolwa kwe-Radiographic | I-hydrogen esebenzayo Ml/100g | ||

| -50 ℃ | -60 ℃ | ||||||

| I-AWS A5.5 E11018M | 680- 760 | ≥760 | ≥20 | ≥27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 | ≥760 | ≥18 | ≥27 | - | I | - |

| I-GEL-118M | 750 | 830 | 21.5 | 67 | 53 | I | 3.2 |

| I-AWS A5.5 E1101X-G | ≥670 | ≥760 | ≥15 | - | - | I | - |

| I-ISO 18275B E761X-GA | ≥670 | ≥760 | ≥13 | - | - | I | - |

| I-GEL-758 | 751 | 817 | 19.0 | 90 | 77 | I | 3.4 |

| I-GEL-756 | 764 | 822 | 19.0 | 95 | 85 | I | 3.6 |

Bonisa:

1. U-"X" omakwe ngefonti ebomvu ku-American Standard kanye ne-European Standard imele uhlobo lwesikhumba sesidakamizwa.

2. I-GEL-758 ihambisana ne-E11018-G ne-ISO 18275-B E7618-G A kumazinga we-AWS kanye ne-ISO ngokulandelanayo.

3. I-GEL-756 ihambisana ne-E11016-G kanye ne-ISO 18275-B E7616-G A kumazinga we-AWS kanye ne-ISO ngokulandelanayo.

Izakhiwo zemishini ye-Q690 steel welding rod esimweni sokwelashwa kokushisa

| Into | Izici zemishini zombuso wokuphathwa ukushisa | ||||||

| Khipha i-MPA | Tensile MPA | Nweba % | Isakhiwo somthelela J/℃ | Ukushisisa ℃*h | |||

| -40 ℃ | -50 ℃ | -60 ℃ | |||||

| Umgomo wephrojekthi | ≥670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570*2 |

| I-GEL-118M | 751 | 827 | 22.0 | 85 | 57 | - | 570*2 |

| I-GEL-758 | 741 | 839 | 20.0 | 82 | 66 | 43 | 570*2 |

| I-GEL-756 | 743 | 811 | 21.5 | 91 | 84 | 75 | 570*2 |

Bonisa:

1. Amazinga ahlobene ne-AWS kanye ne-ISO awanazo izimfuneko zokusebenza kokwelashwa kokushisa kule mikhiqizo engenhla. Ukwelashwa kokushisa okungenhla kufinyezwa ngokusekelwe ezimeni zobuchwepheshe zamakhasimende amaningi futhi kungokwereferensi kuphela.

2. I-GEL-118M inokuqina komthelela okuhle kakhulu ku--40°C ngemva kokwelashwa kokushisa, futhi ukuwohloka komthelela ku -50°C kubonakala kakhudlwana.

3. Ngemva kokwelashwa kokushisa, i-GEL-758 inokuqina komthelela okuhle kakhulu ku--40°C, ukuqina komthelela omuhle ku--50°C, kanye nokonakala okusobala ekushiseni okuphansi kokuthi -60°C.

4. Ukuwohloka kokuqina komthelela wezinga lokushisa eliphansi kwe-GEL-756 ngemva kokwelashwa kokushisa kuncane uma kuqhathaniswa, futhi ukuqina kwezinga lokushisa eliphansi kokuthi -60°C kusekuhle.

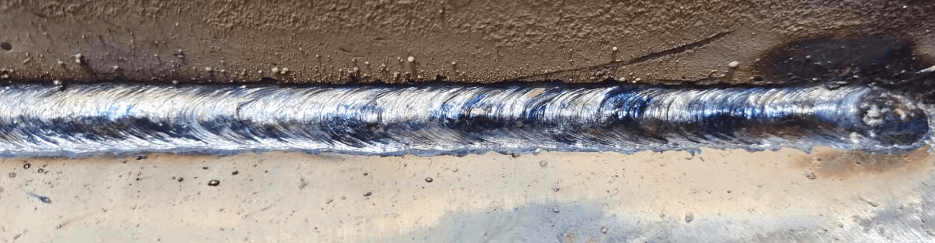

Ukuboniswa kokushisela kwenduku yokushisela yensimbi ye-Q690

1.I-Flat fillet welding (φ4.0mm)

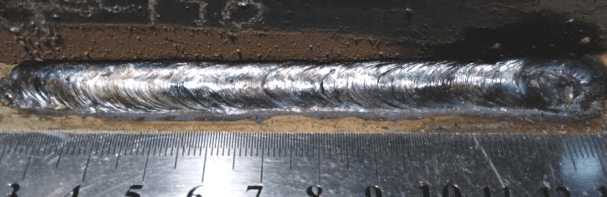

I-GEL-118M flat fillet welding ngaphambi nangemva kokususwa kwe-slag (DC+)

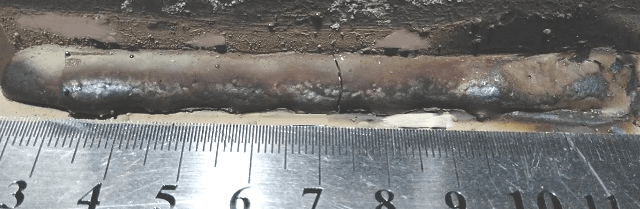

Ngaphambi nangemuva kwe-GEL-758 flat fillet welding slag ukususwa (DC+)

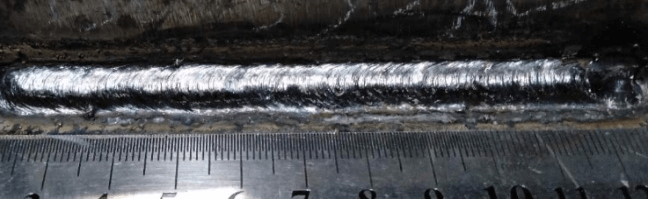

I-GEL-756 flat fillet welding ngaphambi nangemva kokususwa kwe-slag (AC)

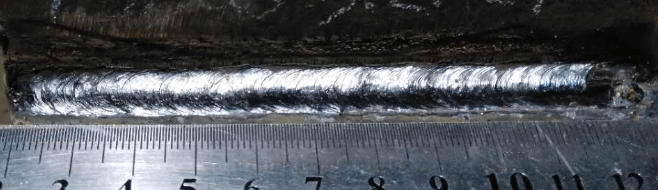

I-GEL-756 i-flat fillet welding ngaphambi nangemva kokususwa kwe-slag (DC+))

Izinyathelo zokuphepha ze-Q690 zensimbi yokushisela induku yokushisela

1. Ukugcinwa kwezinto ezisetshenziswayo zokushisela:

I-Welding Consumables inconywa ukuthi igcinwe ngaphansi kwezimo zokushisa nezimo ezomile, futhi ibekwe kuma-pallets noma amashalofu, igweme ukuthintana ngqo nezindonga nomhlabathi.

2. Ukulungiselela ngaphambi kokushisela:

Khipha kahle umswakama, ukugqwala, amabala kawoyela, njll. endaweni eyisisekelo, futhi ugweme umswakama ongaphezulu noma ukuchayeka emvuleni naseqhweni.

3. Izinyathelo zokuvikela umoya:

Uma kushiswa, kufanele kuqinisekiswe ukuthi isivinini esikhulu somoya endaweni yokushisela asidluli ku-2m/s. Uma kungenjalo, izinyathelo zokuzivikela kufanele zithathwe.

4. Ukushisa kuqala:

Kunconywa ukusebenzisa izinto zokushisisa zikagesi ukushisisa isiqeshana somsebenzi sibe ngaphezu kuka-150°C ngaphambi kokushisela. Ngisho nangaphambi kwe-tack welding, kufanele ifudumale ibe ngaphezu kuka-150°C.

5. Ungqimba nokulawula izinga lokushisa lomgwaqo:

Phakathi nenqubo yonke yokushisela, izinga lokushisa le-interpass akufanele libe ngaphansi kwezinga lokushisa langaphambi kokushisa, futhi izinga lokushisa elinconywayo lokudlula liyi-150-220 ° C.

6. Ukususwa kwe-hydrogen ngemva kokushisela:

Ngemuva kokuthi umthungo we-weld usushiselwe, ngokushesha wandise izinga lokushisa lokushisa kagesi libe ngu-250 ℃ ~ 300 ℃, ligcine lifudumele amahora angu-2 kuya kwangu-4, bese upholisa kancane.

① Uma ubukhulu bomsebenzi wokusebenza bungu-≥50mm, isikhathi sokubamba kufanele sinwetshwe sibe ngamahora angu-4-6, bese sipholiswa kancane.

② Ngaphansi kwezimo zokujiya okukhulu nokuvimbela okukhulu, i-dehydrogenation eyodwa eyengeziwe ingangezwa ngemva kokushisela ku-1/2 ukujiya, futhi kupholiswe kancane kancane kumazinga okushisa e-interpass.

7. Isakhiwo saphansi:

Kunconywa ukusebenzisa i-multi-layer kanye ne-multi-pass welding, futhi isivinini se-welding kufanele sigcinwe ngesivinini esingaguquki.

More information send to E-mail: export@welding-honest.com

Isikhathi sokuthumela: Jan-10-2023