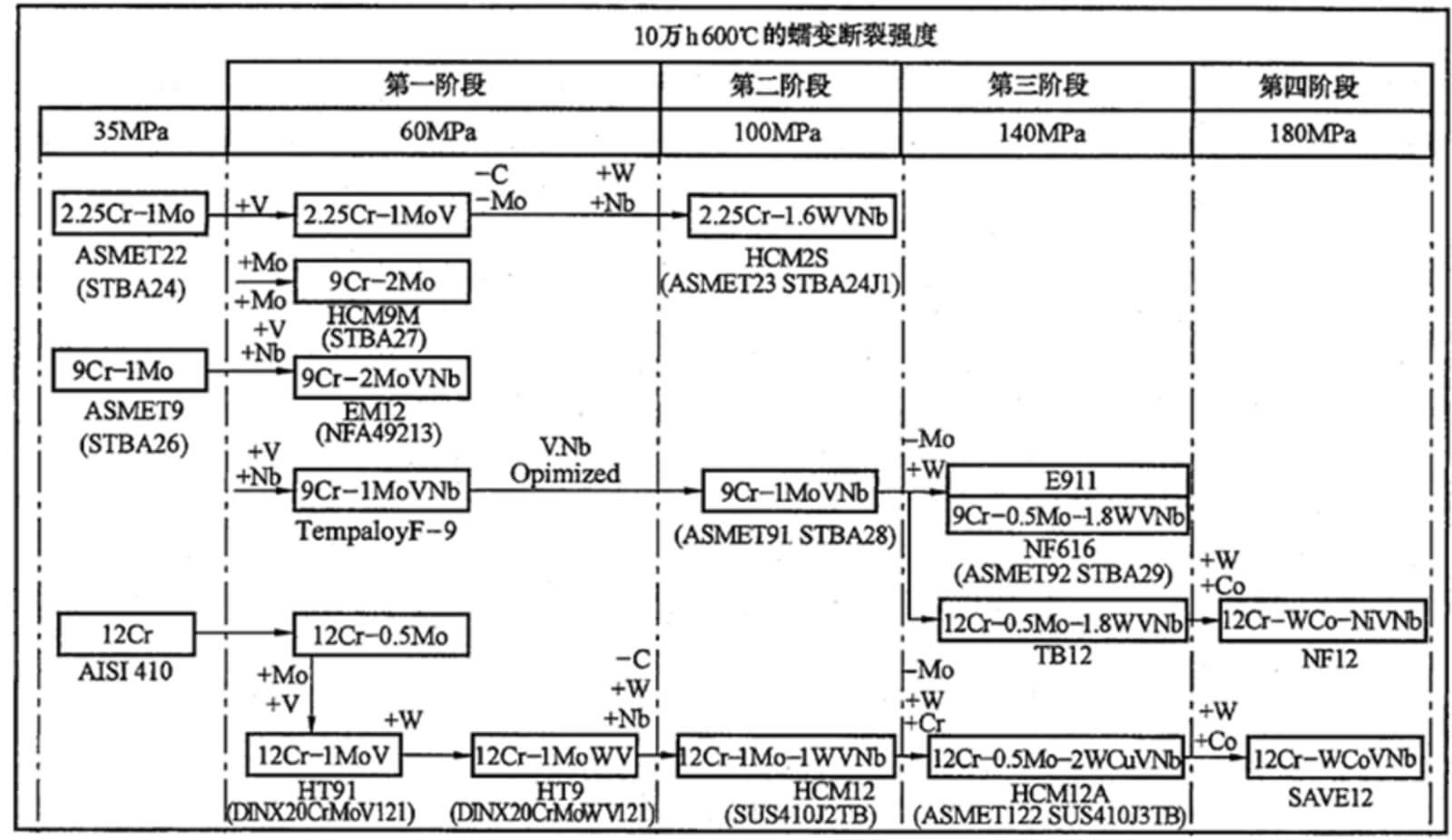

Ukuthuthukiswa kwensimbi ye-ferritic ekwazi ukumelana nokushisa

Khulisa i-Cr-1.25Cr iye ku-12Cr

Engeza V, Nb, Mo, W, Co, njll.

Umkhuba wokuthuthukiswa kwensimbi ye-ferritic ukumelana nokushisa

Qaphela:

Ngokomkhuba wamazwe ngamazwe, izinsimbi ezibizwa nge-pearlite, bainite, kanye ne-martensitic ezimelana nokushisa kuma-boiler nezinsimbi zamaphayiphi zihlangene zibizwa ngokuthi "izinsimbi ze-ferritic ezimelana nokushisa".

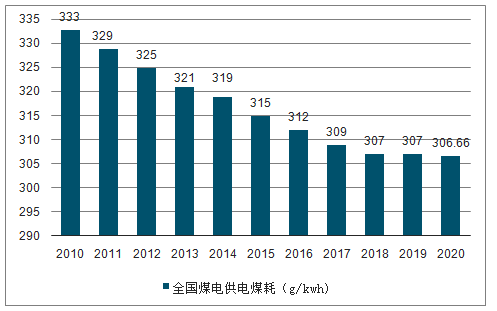

Ngokulungiswa kwesakhiwo samandla ezwe lami kanye nokuthuthukiswa kokwakhiwa kokuphakelwa kukagesi, ukusebenza kahle okuphezulu, ukuhlanzeka, nokunobungani kwemvelo amayunithi amakhulu namapharamitha aphezulu asebe namandla. Ngokwandisa imingcele yesitimu (ingcindezi nezinga lokushisa), ingathuthukisa ngempumelelo ukusebenza kahle kweyunithi, inciphise ukusetshenziswa kwamalahle, futhi inciphise ukukhishwa kwe-CO2. Njengamanje, indlela eyinhloko yokuthuthukisa ukusebenza kahle kwamayunithi wamandla ashisayo ukuthuthukisa amapharamitha we-steam nokuthuthukisa amayunithi we-supercritical (SC) kanye ne-ultra-supercritical (USC). Njengamanje, kunamayunithi angaphezu kwezigidi eziyi-100-kilowatt ultra-supercritical (USC) asetshenziswa ezweni lami, akleliswe endaweni yokuqala emhlabeni kokubili ubuningi nomthamo ophelele.

Izibalo kanye Nesibikezelo Sokusetshenziswa Kwamalahle Kokuhlinzekwa Kwamandla Amalahle e-China kusukela ngo-2010 kuya ku-2020

2.Imikhiqizo eyinhloko ye-Chromium Molybdenum Steel Welding Rod

Ithebula 2 Isibonisi sokusebenza sama-electrode ensimbi amelana nokushisa kwepearlitic

| Into | Isithako esiyinhloko | Ukushisa℃*H | Ukuziphatha kwemishini | ||||

| Veza Mpa | I-tensile Mpa | Nweba % | Ukwethuka J/℃ | ||||

| I-GER-107 | 0.5%Mo | 620*1 | 477 | 570 | 24.0 | 152/0 | - |

| I-GER-207 | 0.5%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 143/0 | - |

| I-GER-307 | 1.25%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 146/0 | - |

| I-GER-317 | 1.25%Cr-0.5%Mo-V | 730*2 | 541 | 635 | 22.5 | 166/0 | - |

| I-GER-407 | 2.25%Cr-1%Mo | 690*1 | 586 | 682 | 21.0 | 142/0 | - |

| I-GER-417 | 2.25%Cr-1%Mo-V | 720*8 | 556 | 657 | 21.0 | 145/-18 | 120/-30 |

| I-GER-507 | 5%Cr-0.5%Mo | 740*1 | 490 | 605 | 23.0 | 124/0 | - |

Qaphela:

1. Inkampani yethu ithuthukise i-EXXXX-15, EXXXX-16, EXXXX-18 nolunye uchungechunge lwe-slag lokumboza lwama-electrode ebanga elifanayo ukuze kuhlangatshezwane nezidingo zemakethe ezahlukene. Okungenhla kukhombisa kuphela ukusebenza kwama-electrode e-EXXXX-15.

3.2 Uhlu lwama-electrodes ensimbi angangeni ekushiseni kanye naphezulu (ultra)

| ITEM | IZINGA | Umlingiswa Omkhulu |

| I-GER-707 | AWS A5.5 I-E8015-B8 I-GB/T 5118 I-E6215-9C1M | 9%Cr-1%Mo Carbon steel core wire, ukwakheka kwealloy okuyinhloko kuguqulwa kusukela ekunameni, kulungele amayunithi angaphansi kwamandla ashisayo, i-A213-T9, i-A335-P9 yensimbi yokushisela (ezomnotho futhi esebenzayo, umsebenzi omuhle) |

| I-GER-91 Uhlobo oluyinhloko | AWS A5.5 I-E9015-B91 I-GB/T 5118 I-E6215-9C1MV | I-9% Cr-1% Mo-Nb-vn Ifanele amayunithi abalulekile wamandla ashisayo, i-T/P 91 steel welding, ukwakheka kwe-alloy okuyinhloko kudluliselwa ku-welding core, izinga lokushisa eliphezulu le-microstructure kanye nokuzinza kokusebenza |

| I-GER-91M izidakamizwa isikhumba core | I-9% Cr-1% Mo-Nb-VN Ifanele amayunithi abalulekile wamandla ashisayo, i-T/P 91 steel welding, ukwakheka kwe-alloy okuyinhloko kudluliselwa ku-welding core, izinga lokushisa eliphezulu le-microstructure kanye nokuzinza kokusebenza. | |

| I-GER-92 Uhlobo oluyinhloko | AWS A5.5 I-E9015-B92 | 9%Cr-0.5%Mo-WV-Nb-N Ifanelekela amandla ashisayo amayunithi angaphezu kwe-supercritical, i-T/P 92 steel welding, ukwakheka kwe-alloy okuyinhloko kuguqulwa kusuka kuntambo eyinhloko, izinga lokushisa eliphezulu le-microstructure kanye nokuzinza kokusebenza |

| I-GER-93 | Izinga lethu | 9%Cr-3%W-3%Co-Cu-V-Nb-B Ifanele ukushiselwa kwensimbi esezingeni eliphezulu ye-G115 esezingeni eliphezulu yokukhiqiza amandla ashisayo. Inesakhiwo esihle nokuzinza kokusebenza ekushiseni okuphezulu. Amandla ahlala isikhathi eside ayi-1.5 izikhathi zensimbi ye-P92, futhi ukumelana kwayo nokushisa okuphezulu kwe-steam oxidation kanye nokugqwala kungcono kunokwensimbi ye-P92. |

Isibonisi sokusebenza kwe-Electrode

| Into | Isithako esiyinhloko | Ukushisa℃*H | Ukuziphatha kwemishini | |||

| Veza Mpa | I-tensile Mpa | Nweba % | Ukwethuka J | |||

| I-GER-707 | 9%Cr-1%Mo | 740*1 | 540 | 670 | 24.0 | 119.7 |

| I-GER-91 | 9%Cr-1%Mo-Nb-VN | 760*2 | 557 | 702 | 21.0 | 96.3 |

| I-GER-91M | 9%Cr-1%Mo-Nb-VN | 760*2 | 553 | 701 | 22.5 | 81.0 |

| I-GER-92 | 9%Cr-0.5%Mo-WV-Nb-N | 760*2 | 596 | 706 | 21.5 | 103.0 |

| I-GER-93 | 9%Cr-3%W-3%Co | 770*4 | 580 | 720 | 20.0 | 77.7 |

Qaphela:

1. I-GER-91M iguquguqukayo, okungukuthi, i-welding core iyintambo evamile ye-carbon steel core, futhi i-alloy eyinhloko iguqulwa ngokufaka. Uma kuqhathaniswa ne-GER-91 (uhlobo lwe-core wire transition), inezinzuzo ezingcono zezomnotho futhi ingcono kakhulu yethu Imikhiqizo eyinhloko yezinduku zokushisela zamandla ashisayo ashisayo.

3.Inguqulo ka-2015 yezinga le-ASME lidinga i-E9015-B91 electrode Mn+Ni≤1.4%, futhi inguqulo yango-2017 idinga ≤1.2% yesisekelo sensimbi. (Inguqulo yakamuva ka-2021 ye-ASME iyaqhubeka nokusebenzisa inguqulo yango-2015 yezidingo zokuqamba ze-ASME zama-electrode E9015-B91/ B92). Ukuze kuhlangatshezwane nesidingo semakethe, izinduku zokushisela ze-E9015-B91 kanye ne-E9015-B92 zenze izinhlobo ezimbili zezinto zokushisela ezihambisanayo: Mn+Ni≤1.4% kanye ne-Mn+Ni≤1.2%. Ngenxa yokuthi lesi sakamuva sinesidingo esiningi semakethe, okungenhla kukhombisa ama-electrode angama-91/92 afakwe insimbi engu-Mn+Ni≤1.2%.

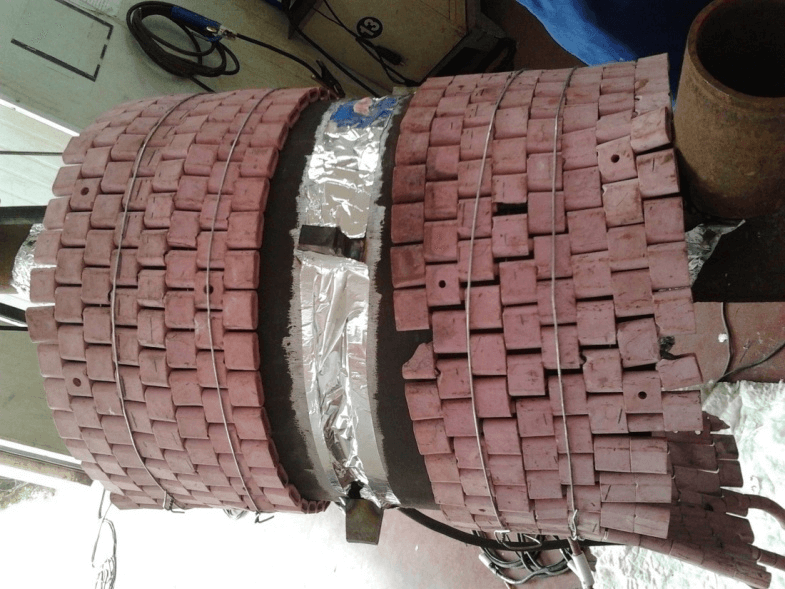

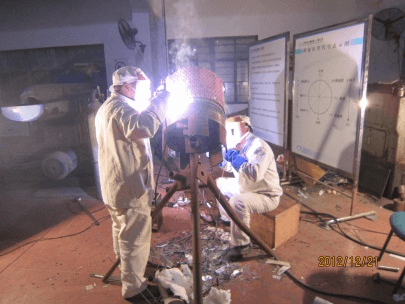

4. Ukuboniswa kokuhlolwa kwenqubo yama-electrode e-ultra-supercritical

4.1 Ukufaneleka kwenqubo yamajoyinti ashiselwe P91/92

6. Izinzuzo nezici zama-electrode ethu ensimbi angangeni ekushiseni wensimbi ye-chrome-molybdenum

1. Kunezinhlobo eziningi nazo zonke izinhlobo

●Ukwakheka kusuka ku-0.5%Mo kuye ku-9%Cr-3%W-3%Co.

●Sebenzisa izinga lokushisa ukusuka ku-500℃ ukuya ku-650℃.

● Imibala ehlukene yokumboza nezinhlobo zokumboza (EXXXX-15, EXXXX-16, EXXXX-18) ingasetshenziswa ezikhathini ezihlukene (uhlobo olujwayelekile, uhlobo oluqinile lwe-arc lwamapayipi okwakhiwa kwamandla).

●Ingakwazi ukuhlangabezana nezidingo zokushisela zezinsimbi eziningi ze-Cr-Mo.

2. Ukusebenza kahle

Izakhiwo ezinhle kakhulu zemishini, ukusebenza kahle kokushisa okuphezulu (izinga lokushisa eliphakeme likhuphuka kanye nezindawo zokushisa eziphakeme zokuguga).

3. Ubuciko obuhle

I-electrode ine-manufacturability enhle kakhulu kuzo zonke izikhundla, ukushiswa kwe-arc okuzinzile, ukuqina okuhle namandla aphefumulayo, i-spatter encane, i-fluidity enhle, i-weld shape enhle, nokususwa kwe-slag kalula ngemva kokushisela.

4. Imboni ehamba phambili

Isebenzisana ne-Suzhou Institute of Thermal Engineering, futhi yaphasisa ukubuyekezwa “komhlangano we-T/P 91/92 Localization Appraisal Meeting” ngo-2015, futhi yabambisana namayunithi amakhulu asekhaya afana ne-Shenhua Guohua kanye ne-General Iron and Steel Research Institute ukuthuthukisa u-650°C. I-G115 steel esekela izinto zokushisela nezinqubo , futhi yabamba imihlangano yokushintshiselana ngezinto ezisetshenziswayo zokushisela.

More information send to E-mail: export@welding-honest.com

Isikhathi sokuthumela: Dec-27-2022