I-MIG Welding Wire Yensimbi Engagqwali i-ER430LNb yekhoyili yentambo yokushisela umkhumbi wezimpahla

UBUCHWEPHESHE bokushisela

Ungavumeli imibuzo

Qhubeka nokukuhlupha

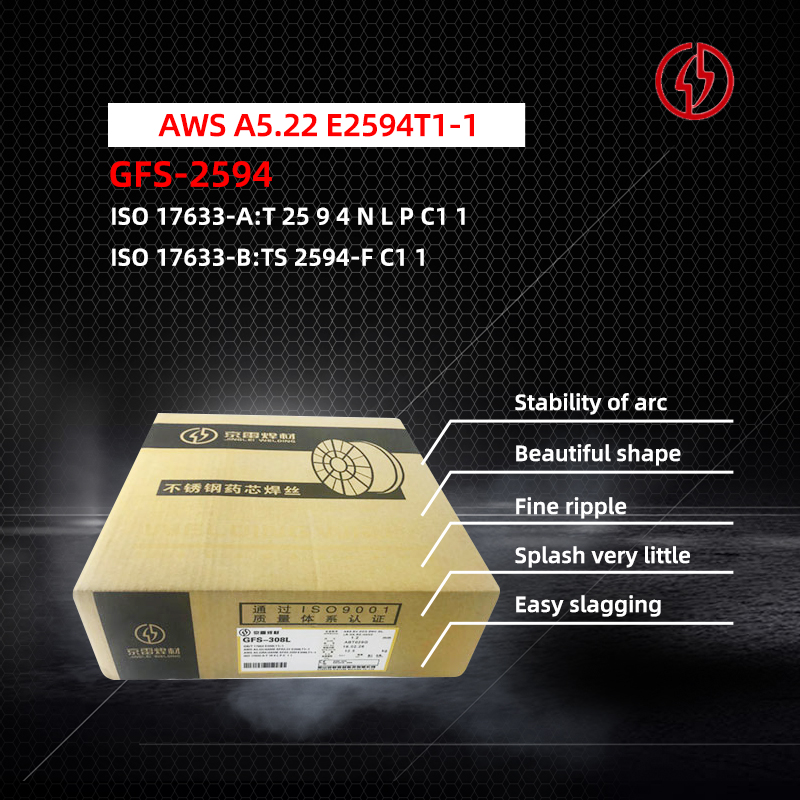

Ukungazinzi kwe-arc

Ukubumba okungabukeki

I-spatter eyeqile

Ilungele ukushiselwa kohlobo lwe-17Cr insimbi engagqwali,

kodwa futhi efanelekayo Welding of yokukhiqiza

ukumelana ne-oxidation kanye nemishini yokumelana nokugqwala

Okufana nokushiselwa kwezingxenye zesistimu yezithulisi (ezifana ne-430, 436, njll.).

Ripple kahle

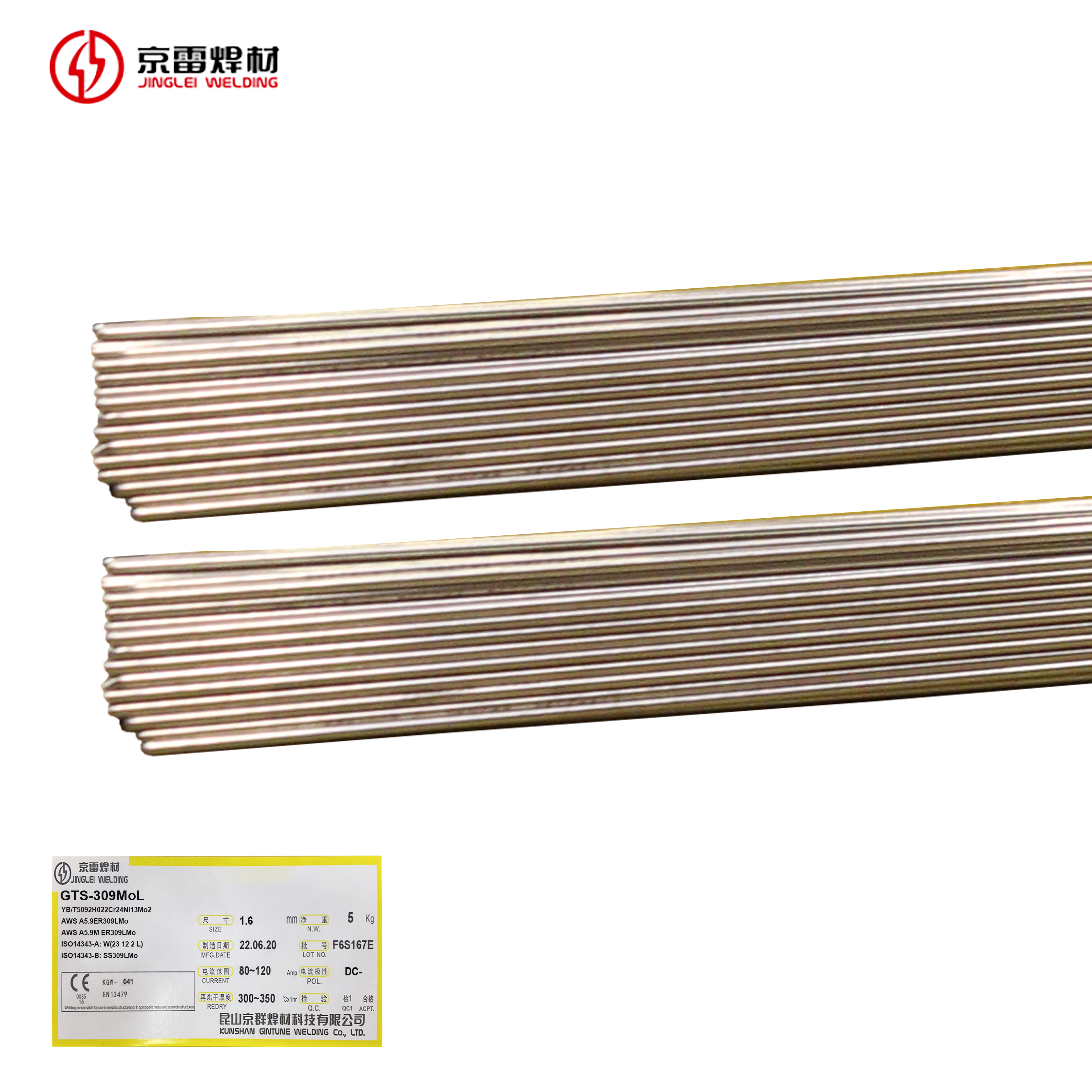

Izici zemishini ye-fused

insimbi izinzile, izinga le-X-Ray elifanelekayo liphezulu

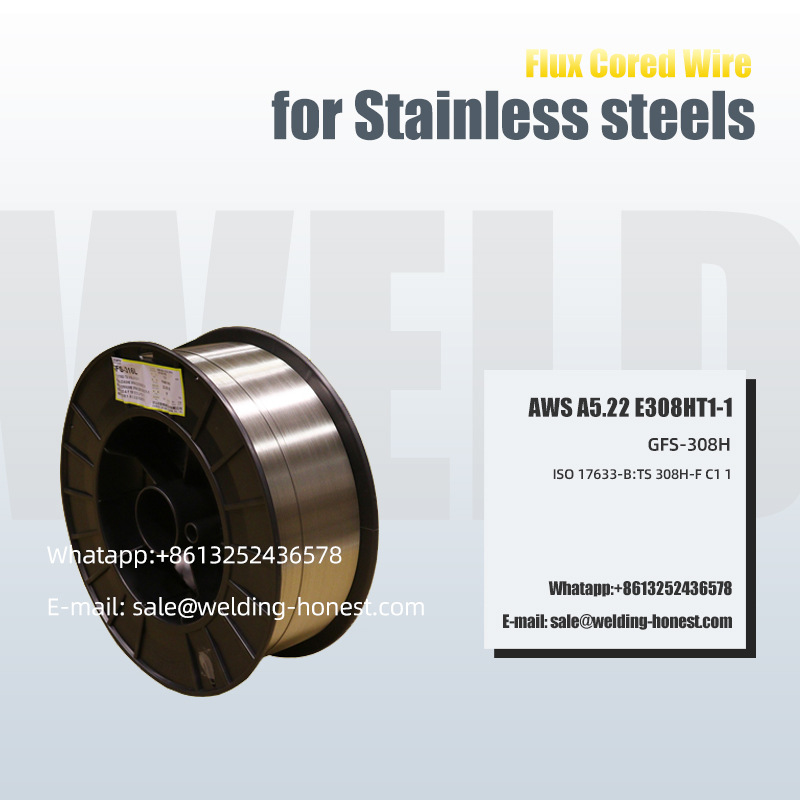

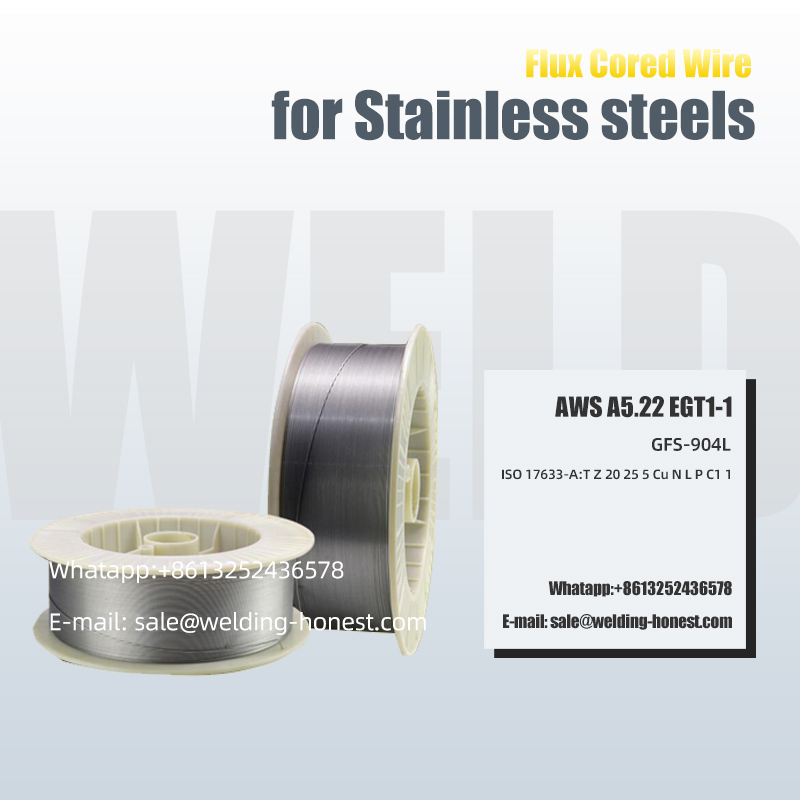

I-wire feed ibushelelezi, i-arc izinzile, ukwakheka kuhle,

i-spatter incane, futhi inqubo yokushisela inokusebenza okuhle kakhulu.

I-slagging elula

Ipharamitha Yomkhiqizo

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMITHETHO | 0.016 | 0.9 | 0.5 | 0.024 | 0.005 | 0.35 | 17.54 | 0.01 | - |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | Ubude/% | IMAPACT VALUE J/℃ | Ukwelashwa kokushisa °C*h | |||||

| GB/T IMITHETHO | - | 475 | 28 | - | 780*2 | |||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 0.8 | 1.0 | 1.2 | ||||

| Ugesi (Amp) | H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Ukwesekwa kwefekthri

Umkhiqizo ufanele a

anhlobonhlobo izicelo

UBUCHWEPHESHE bokushisela

I-boiler yokusetshenziswa

I-981 semi-submersible drilling rig

Ithangi lomjovo lokuphepha

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Okunye |

| GB/T IMITHETHO | 0.016 | 0.9 | 0.5 | 0.024 | 0.005 | 0.35 | 17.54 | 0.01 | - |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | Ubude/% | IMAPACT VALUE J/℃ | Ukwelashwa kokushisa °C*h | |||||

| GB/T IMITHETHO | - | 475 | 28 | - | 780*2 | |||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 0.8 | 1.0 | 1.2 | ||||

| Ugesi (Amp) | H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||