I-ISO 3581-A Izesekeli ze-Stainless steels Manual electrode Welding

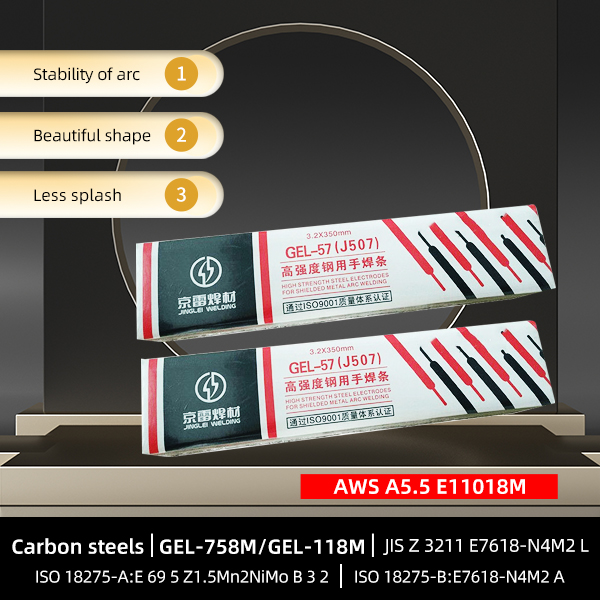

Isicelo&Standard&Note:

1. Ifanele UKUSHISELA I-CARBON Steel KANYE NE-LOW Alloy Steel, KANYE NAMANDLA AHAMBISANA EBHOILE, ipayipi, imoto, IBUILDING, IBHOLOHO KANYE NEZINYE IZAKHIWO, NJENGO-Q345.

2. Izinga esihlangabezane nalo: GB/T5117 E5016, AWS A5.1 E7016 & A5.1M E4916, ISO2560-A:E 42 3 B 1 2, ISO 2560-B: E4916 A

Izinyathelo zokuphepha zokushisela:

Ngaphambi kwe-welding, i-weldment kumele ingabi namafutha, ukugqwala, umswakama, njll.; ukomisa ku-350 ° C ihora; futhi omiswe ngokusetshenziswa

3. Sebenzisa i-pass welding emincane kanye ne-arc welding emfushane; Ukuxhumeka kwe-AC ne-DC kuyahlehla.

Ingasetshenziselwa ukushisela insimbi ye-carbon ephansi kanye ne-490MPa yamandla aphezulu wepayipi lensimbi yensimbi ehlangene, ingakwazi ukuqaphela ukwakheka kohlangothi olulodwa lwe-welding kabili-side.

I-electrode ingeyohlobo oluphansi lwe-hydrogen, ipayipi lokushisela kanye nesakhiwo esijwayelekile sempande ye-weld, ingakwazi ukubona ukwakheka okuhlangene okuhlangene okuhlangene, ngakho-ke ingasindisa isithende sokuhlanza isithende, ukuze ukusebenza kahle kwe-welding kuthuthukiswe. .

Amaphuzu abalulekile enqubo:

1, ukomisa ngaphambi kokusetshenziswa, 300 ~ 350 ℃ omiswe 30 ~ 60 imizuzu;

2, khetha i-current ne-groove efanelekile, ukuze uthole i-weld enhle yasemuva;

3. Uma ucisha i-arc, hola umgodi we-arc ohlangothini lwe-groove bese uphula i-arc;

4. Isikhathi sokuqala se-arc usebenzisa ipuleti lokuqala le-arc noma ohlangothini lwe-groove arc;

5. Gcina i-arc welding emfushane;

6. Sebenzisa uxhumano lwe-AC noma lwe-DC.

Izici

1. I-Titanium calcium i-electrode yensimbi engagqwali, ukwakheka okuyinhloko yi-18% CR-8% Ni-6%Mn;

2. I-arc ezinzile, ukwakheka okuhle, ama-ripples amahle, ama-splashes ambalwa, i-de-slagging elula, ukumelana nomlilo okuhle kwesikhumba sezidakamizwa, ukumelana okuhle kwesisu.

3. Izakhiwo zemishini ezinzile, izinga lokuphasa nge-X-ray liphezulu.

E307-16with Grade (AWS A5.4),Stainless steel welding I-Electrode iwuhlobo oluhlukile lwensimbi yokushisela efana nokushisela i-austenitic manganese kuya ku-carbon steel castings noma ama-forgings.

Asetshenziswa kakhulu embonini yezinhlelo zokusebenza ezahlukahlukene futhi akhiwa ngobuchwepheshe be-urbane kanye nebanga eliphakeme lezinto ezingavuthiwe ezinezici ezintsha kakhulu, Lawa ma-electrode wokushisela we-SS nawo angenziwa ngokwezifiso ahlobene nosayizi nokujiya kwawo ngokwezidingo zamakhasimende.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMITHETHO | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| AWS IMITHETHO | - | - | - | - | - | - | - | - | - |

| ISIBONELO VALUE | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | LONGATION(%) | |||||||||

| GB/T IMITHETHO | 350 | 500 | - | - | 25 | |||||||||

| AWS IMITHETHO | - | - | - | - | - | |||||||||

| ISIBONELO VALUE | - | 635 | - | - | 36 | |||||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| Ugesi (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IMINININGWANE YOKUPAKA:

| UKWEHLUKANA | LENGTH | PCS/1KG | Isisindo/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding

Amacala Ajwayelekile

Isitifiketi

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T IMITHETHO | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| AWS IMITHETHO | - | - | - | - | - | - | - | - | - |

| ISIBONELO VALUE | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | LONGATION(%) | |||||||||

| GB/T IMITHETHO | 350 | 500 | - | - | 25 | |||||||||

| AWS IMITHETHO | - | - | - | - | - | |||||||||

| ISIBONELO VALUE | - | 635 | - | - | 36 | |||||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| Ugesi (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

IMINININGWANE YOKUPAKA:

| UKWEHLUKANA | LENGTH | PCS/1KG | Isisindo/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding