Intambo yokushisela ye-SAW ebheke kanzima nezinto zokwenza izinto zokwenziwa kwe-welding flux

Isicelo & Okujwayelekile

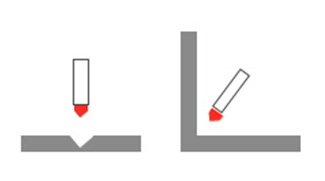

Le electrode yesandla eqinile ye-WEAR emelana nesandla ifaneleka kakhulu ukuba nomthelela ophansi, izingxenye ezigqokile eziqinile, njengokuvuselelwa kabusha kwemishini yokwakha, ikakhulukazi imishini yokudonsa, ibhakede, iphampu yokumunca isihlabathi. I-surfacing iyindlela yokushisela lapho ingaphezulu noma unqenqema lwezingxenye zensimbi luhlanganiswa nongqimba lokumelana nokugqoka, ukumelana nokugqwala, ukumelana nokushisa okuphezulu nezinye izici zezinto zensimbi. Ukulungisa nokuthuthukisa impilo yesevisi yezingxenye, ukusetshenziswa ngempumelelo kwezinto ezingavuthiwe, ukuthuthukisa ukusebenza komkhiqizo, ukulawulwa kwezindleko kunezinzuzo ezisobala zezomnotho. Izinga le-surfacing liyinkimbinkimbi kakhulu. Kuyadingeka ukwamukela i-welding wire efanelekile ngokwemithetho ehlukene. Izinqubo ezihlukene zokubeka phezulu kufanele zisetshenziselwe izingxenye zensimbi ezihlukene kanye nama-electrode angaphezulu ukuze kutholwe imiphumela egculisayo yokuvelela phezulu.

Izici

Lolu uhlobo oluphansi lwe-sodium hydrogen enamathela uhlobo lwe-electrode engaphezulu, ubulukhuni obuphezulu, asikho isidingo sokwelashwa okushisa, ayikwazi ukuqhubeka nokusika, ukumelana nokugqokwa okuhle. I-Wear - Inqubo yokusebenza efanele ingaqinisekisa ukuthi sonke isikhumba singancibilika echibini elincibilikisiwe nge-arc ngesikhathi sokushisela. Futhi i-weld core, i-substrate surface metal iyancibilika ngokushesha ukuze ikhiqize ingxubevange entsha engagugi. Ngesikhathi esifanayo, kufanele kwenziwe imizamo yokuthuthukisa okuqukethwe kwekhabhoni ye-electrode ngesisekelo sokuqinisekisa ukuthi ungqimba lwe-welding lunokumelana okuhle kakhulu kokuqhekeka. Khuthaza ukwakheka kwama-carbides ahlukahlukene, ukwandise ukumelana kwayo nokugqoka. Ezingxenyeni ezithwala umthelela kanye nokuguga okuhubhukayo ngesikhathi esifanayo emsebenzini, njengekhanda lesando le-crusher, i-lining plate, i-cage rod, njll. Ungqimba olungenhla lokushisela kude nokuhlangabezana nezidingo zezimo zalo zokusebenza, futhi kufanele kwamukelwe inqubo yokusebenza ehluke ngokuphelele.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T IMITHETHO | 0.50-0.80 | 0.50-1,50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| AWS IMITHETHO | - | - | - | - | - | - |

| ISIBONELO VALUE | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| Ugesi (Amp) | 80-120 | 120-160 | 160-210 | |||||

AMACALA AJWAYELEKILE

Izitifiketi

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T IMITHETHO | 0.50-0.80 | 0.50-1,50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| AWS IMITHETHO | - | - | - | - | - | - |

| ISIBONELO VALUE | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| Ugesi (Amp) | 80-120 | 120-160 | 160-210 | |||||