I-Cobalt Alloys Manual electrode EDCoCr-B Welding izesekeli

Isicelo

Ingasetshenziselwa ukuveza izinga lokushisa eliphezulu nama-valve omfutho ophezulu, umkhono we-high pressure shaft shaft kanye nomkhono we-lining, i-chemical fibre cutting edge, i-sawtooth, i-screw push rod, njll.

Okukhethekile

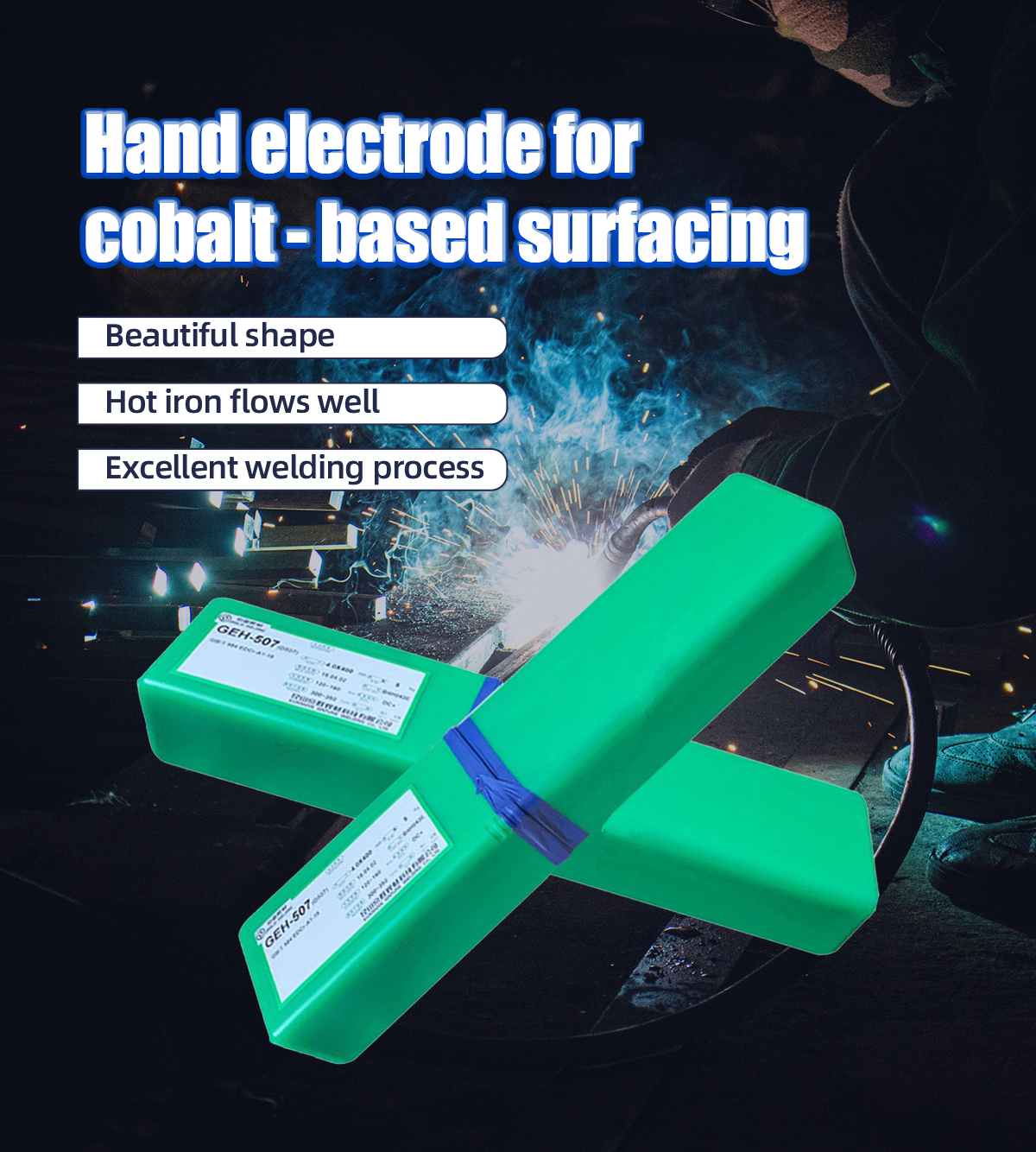

I-electrode engaphezulu esekwe ku-cobalt ehlanganiswe ne-Titanium-calcium enengxubevange ye-cobalt-chromium-tungsten njengoba intambo eyinhloko kufanele yamukelwe.

Sebenzisa i-DC reverse uxhumano.

Insimbi engaphezulu ingagcina ukuguga okuhle nokumelana nokugqwala ku-650 ℃.

Bonisa imininingwane

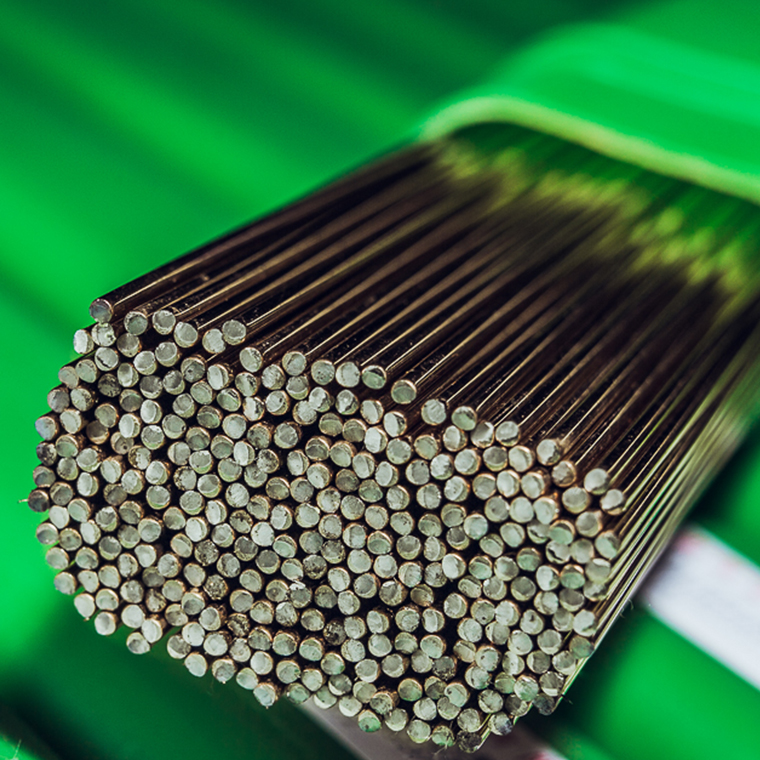

Umumo omuhle

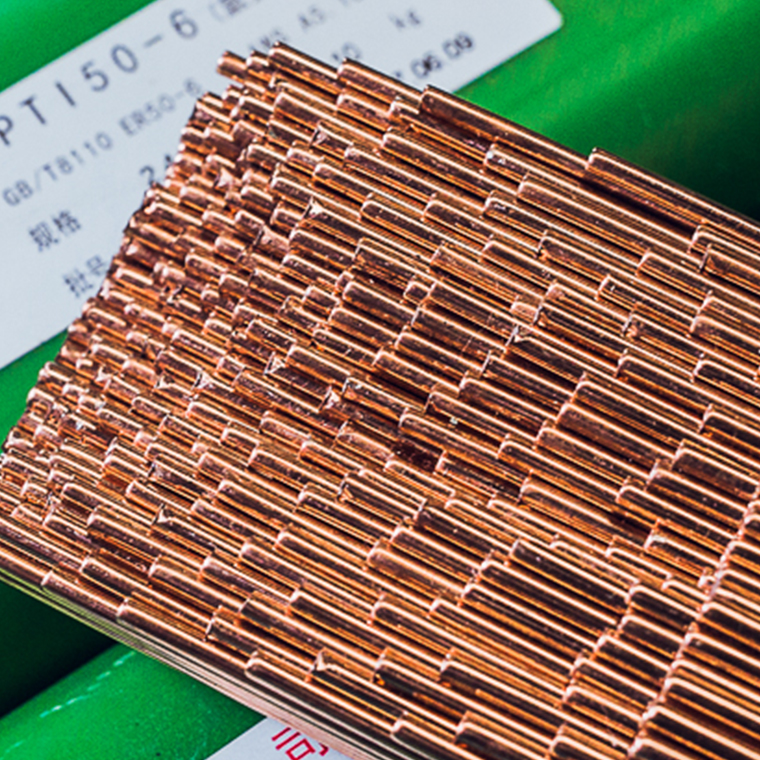

Umumo omuhle

Mayelana NATHI

Isibonisi se-Factory fioor

Icala lesicelo

I-Sino-Russian Eastern Front

I-Hainan Huasheng phenol recovery tower

Ukudubula kwefekthri kwangempela

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T IMITHETHO | 1.00-1.70 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 7.00-10.00 | Imajini |

| AWS IMITHETHO | 1.0-1.7 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 7.0-9.5 | Imajini |

| ISIBONELO VALUE | 1.15 | 1.31 | 1.12 | 30.5 | 2.4 | 0.1 | 3.500 | 8.3 | Imajini |

I-WELD PASS HARDNESS:

Isibonelo senani HRC=46

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Bhala umyalezo wakho lapha futhi usithumelele wona