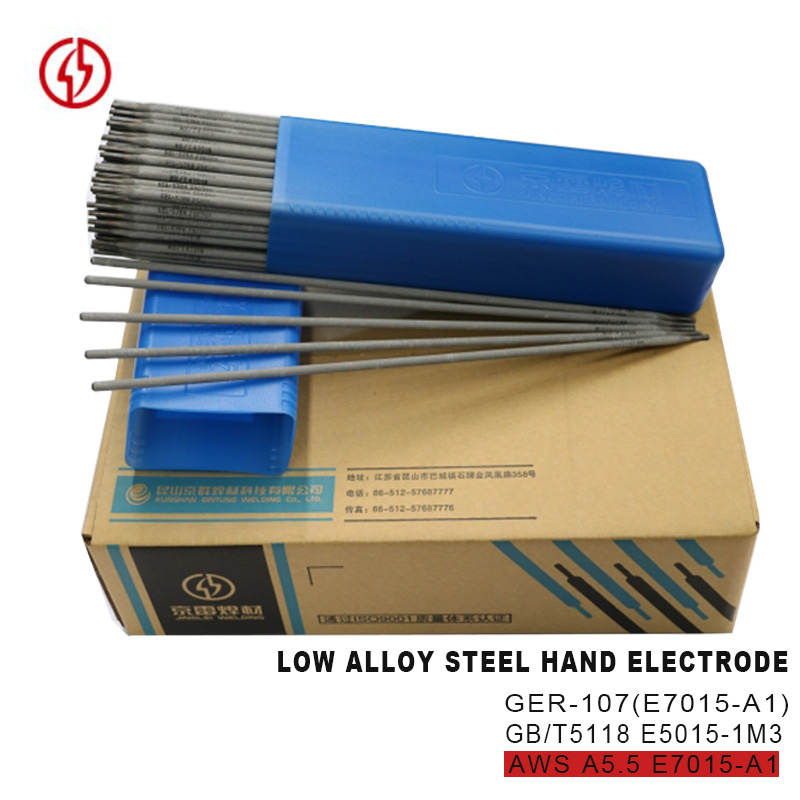

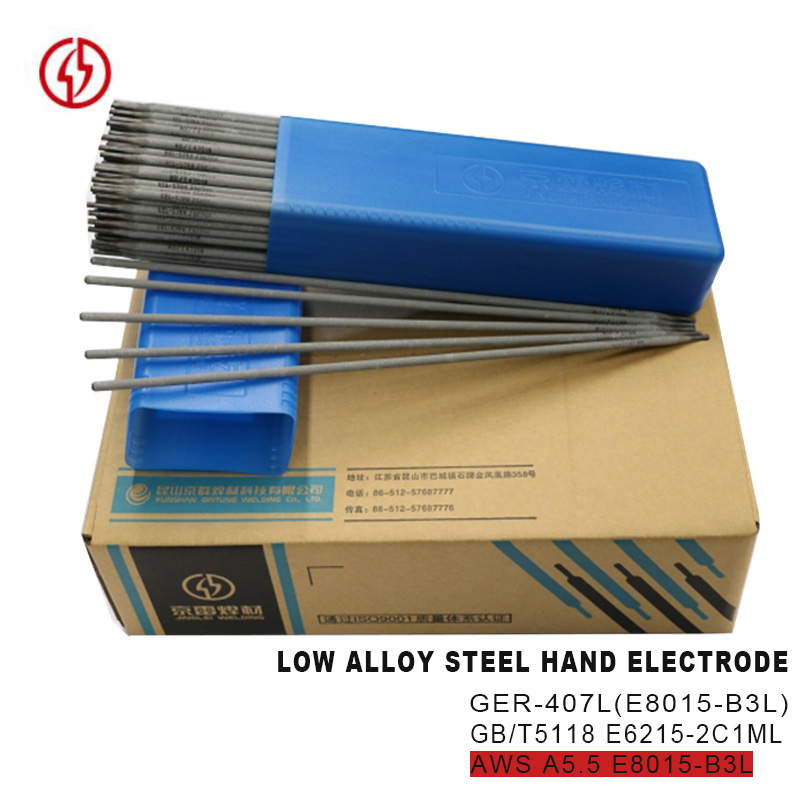

I-AWS E7015-A1 Izinsimbi ze-Low-alloy Manual Electrode Izesekeli zokushisela

Isicelo&Standard&Note:

I-E7015 uhlobo oluphansi lwensimbi yensimbi ye-electrode ilungele ukushisa okusebenzayo kokushisela ngaphansi kuka-510 ℃ kubhayela ipayipi, isishintshi sokushisa nezinye izikhathi, njengepayipi le-ASTM A204 ne-A335-P1;

I-electrode kumele yomiswe ngaphambi kokusetshenziswa, gcina i-arc emfushane, ukusetshenziswa kwendlela yokubuyela emuva ye-welding, gwema ukuvela kwe-porosity ku-arc; I-hydrogen ephansi kufanele igcinwe kuyo yonke inqubo yokushisela. Ukukhetha okuphansi kwe-electrode yensimbi ye-alloy, imvamisa ngokuya ngokwakheka kwamakhemikhali ensimbi, izakhiwo zemishini, ukumelana nokuqhekeka nezinye izidingo, kodwa futhi kusukela ekubunjweni kwesakhiwo sokushisela, izimo zokusebenza, ingcindezi nemishini yokushisela nezinye izici zokucatshangelwa okuphelele. Uma kunesidingo, ukuhlolwa kokusebenza kwe-welding kuzokwenziwa ukuze kunqunywe i-electrode kanye nezinyathelo zenqubo ezidingekayo zizothathwa.

Izici

1. I-sodium hydrogen electrode ephansi, enezela i-0.5% Mo ukuthuthukisa amandla e-weld nokumelana nokugqwala;

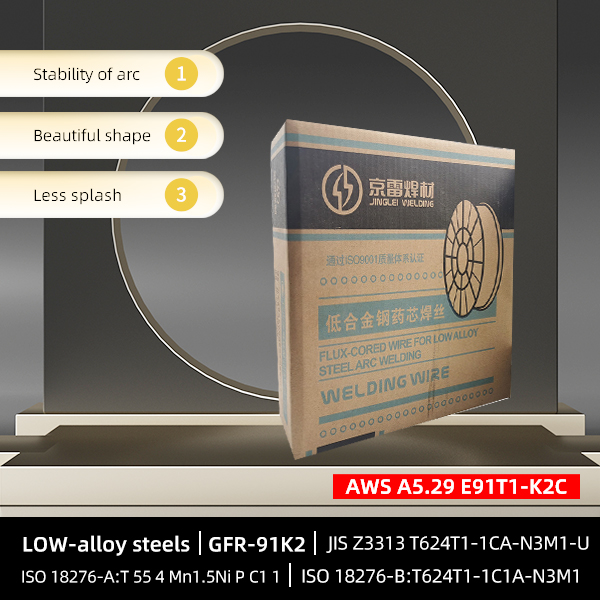

2. I-arc ezinzile, i-splash encane, ukwakheka okuhle, kulula ukuyisusa, ukusebenza kwe-X-Ray kuhle kakhulu.

Ngokuvamile khetha i-electrode ehambisanayo ngokwamandla ebangeni lensimbi, ngasikhathi sinye futhi udinga ukushiselwa kwensimbi, ukuguqulwa kwezakhi zensimbi yomzali, isibindi sokuphendula usayizi wesakhiwo, ukuma, i-groove kanye nezici zokuhlushwa ukucindezeleka, njengokuhlanganisa okuphelele. uma kucatshangelwa, ijubane lokupholisa le-welding likhulu kakhulu, lingamandla aphezulu, imikhiqizo yasemgwaqweni ye-weld iqhekeka kalula izimo ezingezinhle, ngokuvamile ingakhetha okungaphansi kwamandla e-electrode yensimbi yomzali.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T IMITHETHO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| AWS IMITHETHO | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| ISIBONELO VALUE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | LONGATION(%) | |||||||||

| GB/T IMITHETHO | 390 | 490 | 620*1 | - | 22 | |||||||||

| AWS IMITHETHO | 390 | 490 | 620*1 | - | 22 | |||||||||

| ISIBONELO VALUE | 477 | 570 | 620*1 | 150/Izinga lokushisa elivamile | 28 | |||||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Ugesi (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

IMINININGWANE YOKUPAKA:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

Amacala Ajwayelekile

Isitifiketi

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T IMITHETHO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| AWS IMITHETHO | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| ISIBONELO VALUE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | LONGATION(%) | |||||||||

| GB/T IMITHETHO | 390 | 490 | 620*1 | - | 22 | |||||||||

| AWS IMITHETHO | 390 | 490 | 620*1 | - | 22 | |||||||||

| ISIBONELO VALUE | 477 | 570 | 620*1 | 150/Izinga lokushisa elivamile | 28 | |||||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Ugesi (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

IMINININGWANE YOKUPAKA:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||