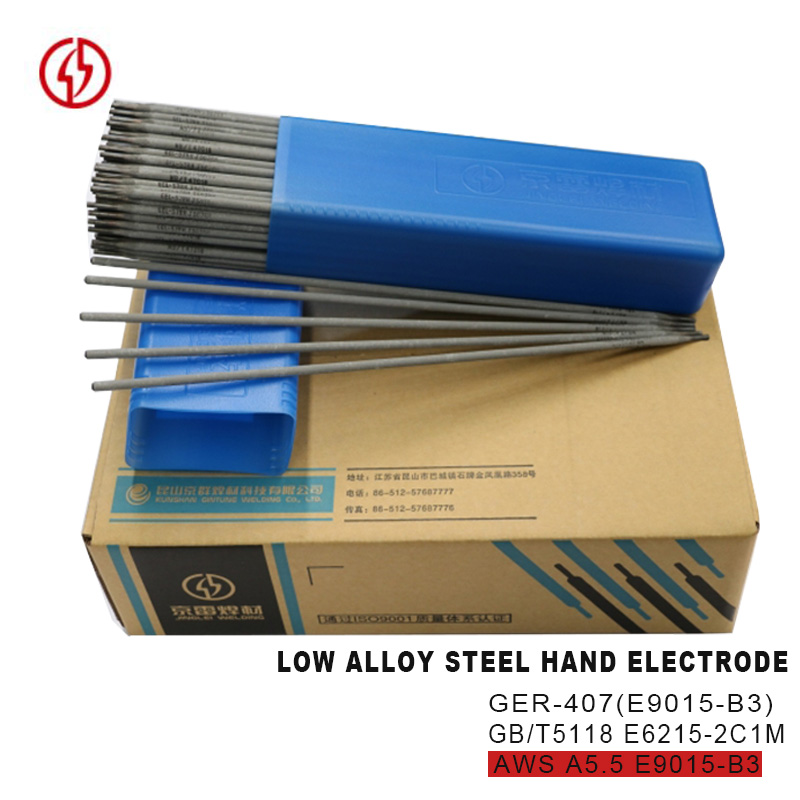

AWS A5.13 ENiCrFe-1 Nickel alloys Manual electrode Welding izesekeli

Isicelo & Okujwayelekile

Le ELECTRODE ESURFACING ESEKELWE ku-COBALT INGASETSHENZISWA EMHLABENI WE-LINING WE-SHAFT SLEEVE, UKUCIKA UCALA LOKUSEBENZA KWE-CHEMICAL FIBBER, SAWTOOTH, SCREW PUSH ROD, izinga lokushisa ELIPHEZULU kanye ne-High pressure valve kanye nepompo yokucindezela OKUPHEZULU NK. Ubukhulu obungaphezulu be-workpiece kufanele bube ngaphansi kuka-Ra12.5μm, futhi ukugqwala okungaphezulu, amafutha nokunye ukungcola kufanele kususwe ngokuqinile. I-matrix akufanele ibe nemifantu, ama-pores, isihlabathi nezinye iziphambeko, futhi imiphetho namakhona kufanele kube yindilinga. Ngaphambi kokuvela phezulu, amazinga okushisa ahlukene kufanele akhethwe ngokusho kwe-substrate material for preheating. Uma okubalulekile kwe-matrix kuyinsimbi ekwazi ukumelana nokushisa noma i-martensitic insimbi engagqwali nezinye izinto ezisebenza kabi ngokushisela, ungqimba olungaphezulu lwensimbi engenasici ye-austenitic kufanele lushiselwe endaweni ye-matrix, bese ingxubevange esekwe ku-cobalt kufanele ivele ngaphezulu ngemva kokucubungula okubushelelezi thuthukisa ukumelana nokuqhekeka futhi ugweme imifantu. Noma ngabe i-AC noma i-DC arc welding power supply ingasetshenziselwa ama-electrode e-D802 kanye ne-D812. Kunconywa ukunikezwa kwamandla we-Dc arc welding.

Izici

I-GEH-SL12 titanium calcium coated cobalt-base electrode engaphezulu. I-Cobalt-cr-tungsten alloy isetshenziswa njengentambo eyinhloko. Kunconywa ukuxhumana kwe-Dc reverse. Insimbi engaphezulu ingagcina ukumelana nokugqokwa okuhle nokumelana nokugqwala ku-650 ℃. Ngaphambi kokushisela, kufanele kubhakwe ku-300-350 ℃ ihora elingu-1; Isendlalelo esiqinile endaweni yensimbi eyisisekelo kufanele sisuswe ukuze kugwenywe imifantu kanye nokonakala. Ngokusho kobukhulu bensimbi eyisisekelo kanye nohlobo lwensimbi eyisisekelo, kufanele ishiswe kuqala ku-300-600 ℃, futhi i-arc welding encane yamanje emfishane ifanelekile.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T IMITHETHO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| AWS IMITHETHO | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| ISIBONELO VALUE | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| Ugesi (Amp) | Ukushisela okuyisicaba/okuvundlile | 69-95 | 70-115 | 95-145 | ||||

| Ukushisela okuqondile/okuphezulu | 55-80 | 65-110 | 80-130 | |||||

AMACALA AJWAYELEKILE

Izitifiketi

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T IMITHETHO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| AWS IMITHETHO | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| ISIBONELO VALUE | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| Ugesi (Amp) | Ukushisela okuyisicaba/okuvundlile | 69-95 | 70-115 | 95-145 | ||||

| Ukushisela okuqondile/okuphezulu | 55-80 | 65-110 | 80-130 | |||||