490Mpa Hand Electrode For High Amandla Steel

Isicelo&Standard&Note

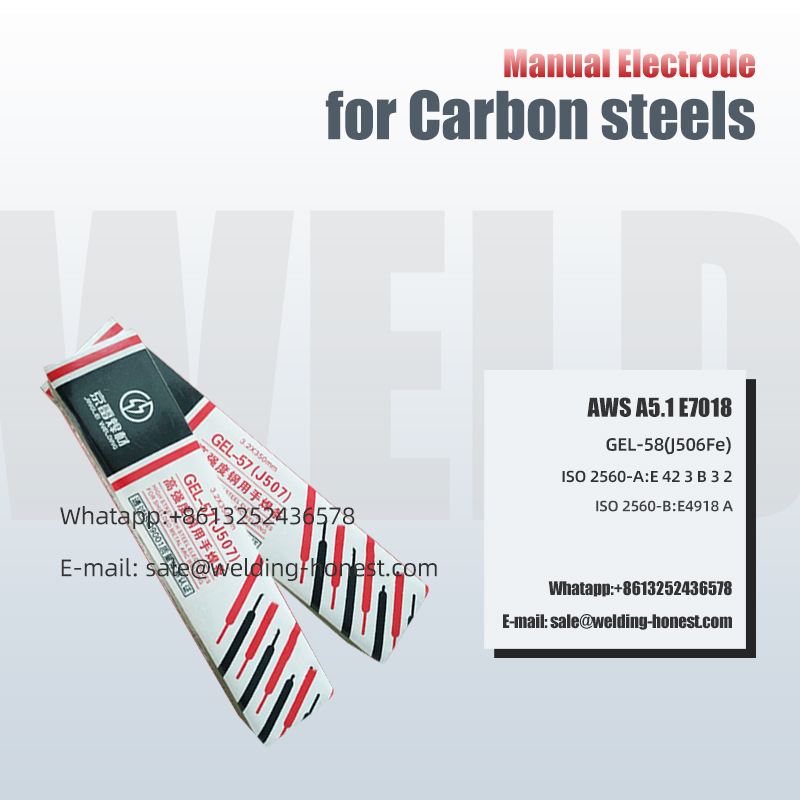

1. Ifanele UKUSHISELA I-CARBON Steel KANYE NE-LOW Alloy Steel, KANYE NAMANDLA AHAMBISANA EBHOILE, ipayipi, imoto, IBUILDING, IBHOLOHO KANYE NEZINYE IZAKHIWO, NJENGO-Q345.

2. Izinga esihlangabezane nalo: GB/T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A:E 42 3 B 3 2, ISO 2560-B: E4918 A

Njengoba i-electrode ye-E7018 imunca kalula umswakama, igcinwa kuhhavini yokomisa i-electrode. I-electrode egcinwe emoyeni ingashintshwa ku-350 ~ 400 ℃ isikhathi esingu-1h ~ 2h. Ukuze ubuyisele izakhiwo zesikhumba. Insimbi ethambile ingashiselwa ngama-electrode e-E7018 angashisiwe, kodwa amandla okugcina e-weld angase angabi phezulu ngokwanele.

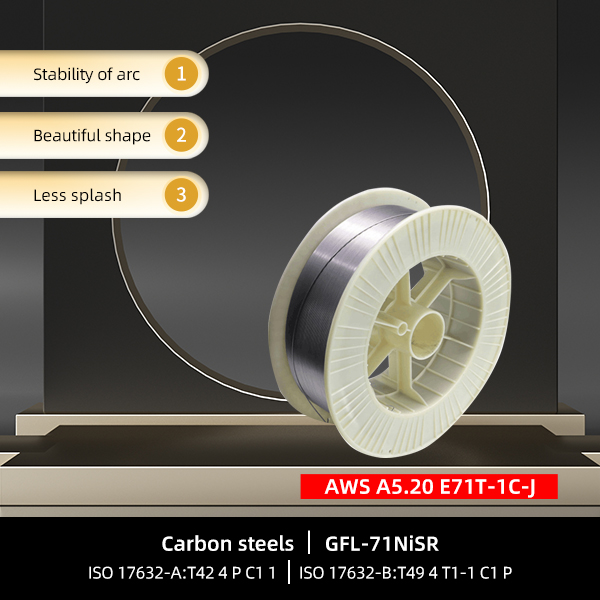

Izici

I-iron powder low hydrogen uhlobo lwe-electrode yesandla, ukusebenza kahle kwe-welding ephezulu, i-arc ezinzile, ukwakheka okuhle, ukubola, ukuchaphaza okuncane, ukukhishwa kalula kwe-slagging, ukumelana okuhle komlilo wesikhumba sezidakamizwa, ukumelana okuhle kwesisu. Izakhiwo zemishini ezinzile, ipulasitiki enhle kanye nokuqina komthelela ophansi wokushisa.

I-E7018 iyikhwalithi ephezulu ye-carbon steel electrode ene-iron powder ephansi ye-hydrogen potassium enamathela. I-electrode inokusebenza okuhle kakhulu kwenqubo yokushisela, ukuqina kwe-arc kuhle, akulula ukukhiqiza ukuvuthwa kwe-magnetic bias, i-welding seam eyenza ihlanzekile futhi inhle, i-splash encane, i-slag kulula; Insimbi ye-weld inokuqina okuhle kakhulu futhi okuzinzile kwezinga lokushisa eliphansi kanye nokumelana nokuqhekeka. Ukusetshenziswa okubili kwe-Ac ne-DC, kungaqhuba yonke indawo yokushisela. Isici saso ukuthi isikhumba sezidakamizwa siqukethe i-iron powder, enganciphisa inani lezingqimba zokushisela. Bhaka i-electrode ku-350 ~ 400 degrees Celsius amahora angu-1 ~ 2, futhi usebenzise nokubhaka. Ngokuvamile le electrode yekhwalithi ephezulu isetshenziselwa ukushisela insimbi yomkhumbi (A, B, D noma E, A36, E36) kanye nezakhiwo ezibalulekile zensimbi ye-low-alloy yezinga elifanayo lamandla, njengama-boilers, imikhumbi yokucindezela kanye namapulatifomu okumba asogwini, njll.

Inkampani Nemboni

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMITHETHO | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| AWS IMITHETHO | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| ISIBONELO VALUE | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | LONGATION(%) | ||||||

| GB/T IMITHETHO | 400 | 490 | AW | 20 | ||||||

| AWS IMITHETHO | 400 | 490 | AW | 22 | ||||||

| ISIBONELO VALUE | 460 | 555 | AW | 30 | ||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| Ugesi | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding

Amacala Ajwayelekile

Isitifiketi

Ukwakhiwa komkhiqizo kanye nezakhiwo zemishini isingeniso

COMPONET YECHEMICAL:

| I-ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T IMITHETHO | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| AWS IMITHETHO | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| ISIBONELO VALUE | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

IMPAHLA YOMKHETHI:

| IMPAHLA | UKUVUMELA AMANDLA(MPa) | AMANDLA AMANDLA(MPa) | I-HEATTREAMENT℃xh | LONGATION(%) | ||||||

| GB/T IMITHETHO | 400 | 490 | AW | 20 | ||||||

| AWS IMITHETHO | 400 | 490 | AW | 22 | ||||||

| ISIBONELO VALUE | 460 | 555 | AW | 30 | ||||||

IMIPHAKATHI YOKUSHISA ENCONYWAYO:

| IZINCACISO ZAMA-DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| Ugesi | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

QAPHELA:

H/W: ukushisela indawo enezingqimba

O/W: i-over-head position welding